Ilmansuodatuksella on merkittävä rooli esimerkiksi tuuli-, lämpö-, ydin- ja biokaasuenergian tuotannossa. Ilmansuodattimet ovat ratkaisevan tärkeitä prosessin turvallisuuden ja tehokkuuden kannalta.

Innovatiiviset ilmansuodatusratkaisut voivat olla kilpailluilla ja säännellyillä markkinoilla kilpailuetu, jolla on merkittävä vaikutus toiminnan kannattavuuteen. Kun tuotantolaitoksen olosuhteet ovat tiedossa, tuloilmajärjestelmät voidaan optimoida toiminta- ja kunnossapitotarpeiden mukaisesti, huoltovälejä voidaan pidentää ja tuotantovolyymia lisätä.

Mitä etsit?

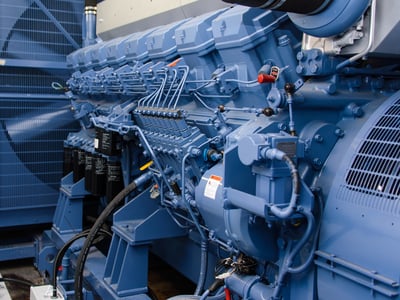

Diesel- ja kaasumoottorit on suojattava sääoloilta, äärimmäisiltä lämpötiloilta sekä epäpuhtauksilta palamisprosessin aikana. Myös ympäristö täytyy suojata kuumilta pakokaasuilta. Kestävät ratkaisut suojaavat painesyöksyjen riskiltä.

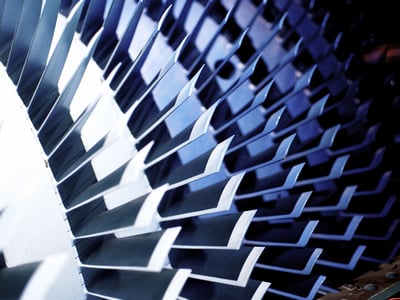

Kaasuturbiinit ovat erittäin tehokkaita ja herkkiä koneita, joita voidaan käyttää sähköntuotannossa tai mekaanisena voimanlähteenä erilaisissa prosesseissa. Kaasuturbiineja käytetään kaikkialla maailmassa, merkittävästikin vaihtelevissa ympäristö- ja käyttöolosuhteissa. Siksi suodatinratkaisu on optimoitava suojaamaan turbiineja asianmukaisesti.

Turbiinikoneistot ja sähkölaitteet, kuten generaattorit, on suojattava sääoloilta ja äärilämpötiloilta asianmukaisesti jäähdyttävällä ilmastoinnilla. Ilmanvaihtoyksikön suojaustaso on optimoitava käyttöympäristön mukaan niin, että laite on suojassa vedeltä, suolalta ja muilta epäpuhtauksilta.

Paineilmakompressorit ovat tärkeä elementti monilla prosessiteollisuuden aloilla, joilla katkoton toiminta riippuu tehokkaasta suodatuksesta. Ympäristö- ja käyttöolosuhteet voivat vaihdella merkittävästi. Siksi suodatinratkaisu on räätälöitävä paikallisiin olosuhteisiin ja toimintoihin.

Camfil on toimittanut ratkaisuja ydinvoimaloille jo 1960-luvun alusta lähtien. Olemme nykyisin maailman johtava ydinhiukkasten ja kaasufaasien suodatusratkaisujen toimittaja, ja meillä on maailmanlaajuista kokemusta yli 90 ydinvoimalasta.

Tuuliturbiineja käytetään usein ankarissa olosuhteissa. Tuloilmasuodattimien on oltava erittäin tehokkaita ja kestäviä, jotta niiden käyttöikä olisi mahdollisimman pitkä ja energiankulutus vähäistä.

Tiesitkö, että Camfil tarjoaa laajan valikoiman korkealaatuisia suodatinpatruunoita ja kasettisuodattimia jälkiasennettavaksi markkinoiden yleisimpiin pölynpoistojärjestelmiin.

Tuotanto ja logistiikka Energiantuotto & Kaasuturbiinit Ruoka ja juoma Biotieteet ja terveydenhuolto

Epäpuhdas ilma heikentää työskentelyolosuhteita jäteveden käsittelylaitoksessa ja aiheuttaa haittoja myös laitoksen ympäristöön. Turun seudun puhdistamon ilmanvaihtojärjestelmät optimoitiin paremmin vastaamaan nykyisiä tarpeita Camfilin avulla

Ilmanlaatu Energiantuotto & Kaasuturbiinit Kestävä Kehitys AsiakastarinatKaikki tuotteitamme ostavat ihmiset eivät ole ilmansuodatuksen asiantuntijoita, eikä heidän myöskään tarvitse olla. Camfil Cityn tarkoituksena on antaa kaikille mahdollisuus oppia perusteet siitä, mitä puhtaan ilman ratkaisumme voivat tehdä heidän hyväkseen.

Dyna Migillä oli kilpailijan pölynkerääjäratkaisu, joka aiheutti säännöllisesti kalliita huoltokatkoja. Camfilin asiantuntemuksen ja lippulaiva Camfil Gold -sarjan GSX-pölynkeräysjärjestelmän avulla Dyna Mig pystyi eliminoimaan kaikki odottamattomat häiriöt työn teossa ja sai pienennettyä lämmityskustannuksia sekä luotua turvallisemman työympäristön.

Pre-filters have an important impact on the overall performance of a filtration system. Choosing the right pre-filter will extend final filter life and also improve overall efficiency.

Jätevesi käy läpi pitkän prosessin Middelfart jätevedenpuhdistamossa, jossa jätevesi käsitellään ja prosessin lopussa siitä tulee lopulta puhdistettua vettä, joka päästetään sitten Middelfartia ympäröivään mereen. Lisäksi sivutuotteena syntyvä biokaasu muunnetaan sähköksi ja lämmöksi sekä biolannoitteeksi, jota käytetään viljelijöiden pelloilla.

Biokaasu voidaan puhdistaa käyttämällä oikeanlaista ja tarkoituksenmukaista molekyylisuodatusta, mikä vähentää moottoreiden syöpymistä ja laitteiden kulumista.

CamPure 32 on Camfilin uusi molekyylisuodatusaines rikkivedyn poistamiseksi biokaasun tuotannon anaerobisen prosessin aikana. Tutustu Case Studyyn.

Case Study: In the gas turbine of a power plant in east China, Camfil China upgraded its pulse filter and retrofitted the prefilter from panel type to pocket type, new solution have been continuously running for more than 9500EOH, while original solution’s lifetime to pressure drop alarm value is less than 2000EOH.