Working in the food and beverage industry, you are aware that without effective filtration, food, beverages and processes can become contaminated due to poor air quality. We’d like to share our knowledge to educate and inspire you to optimise your food and beverage company to meet the strict regulatory industry requirements.

Companies in the food and beverage industry have a responsibility to ensure the safety of all people, products and processes. Food and beverage contamination grabs people’s attention because eating and drinking are vital and necessary parts of everyone’s day.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studies

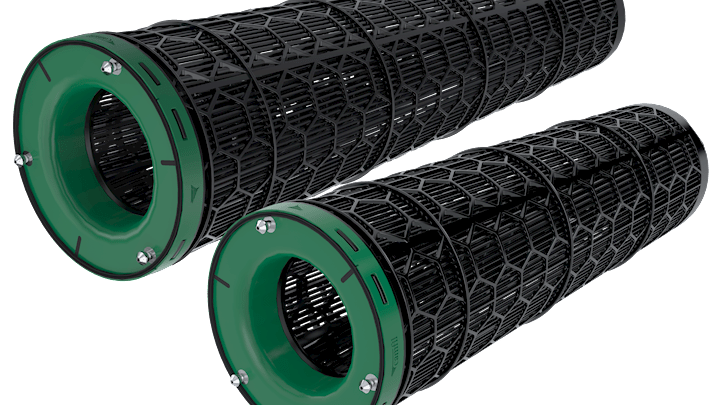

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageAir contamination can occur from anywhere, even outside the premises. The CDC has added airborne transmission as one of the methods that COVID-19 can spread. It is important to highlight the potential risks surrounding the business such as air pollution.

In the realm of controlled environments, where precision, purity, and protection are paramount, high-efficiency particulate air (HEPA) filters emerge as unsung heroes

It is common that meat processing factories are susceptible to the spread of airborne viruses and microbes. Temperature and humidity requirements along with the production processes lend to the survival of airborne microbes and viruses.

Often the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Processes in manufacturing facilities often generate dust and fumes which for example can pose health risks for your operators or compromise the quality and safety of your products. Determining the right capture and filtration solution helps to protect against the main risks of uncontrolled emissions and thus to create safe work environments.

Tonnies Meat Processing Facility - Boosts Air Quality Standards in the Right Places

The new Absolute VG HEPA air filter is all about making your life simpler, safer and more eco friendly. This is achieved by offering you filters that are extremely light-weight, robust and easy to handle. Filters that provide world-leading protection for your operations.

The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Air is a vital ingredient in food and beverage production. Protecting your production process and final product has never been easier.

A commercial bakery eliminates airborne pollutants and dust, improving safety, reducing downtime and lessening the risk of cross-contamination.

Case Study: Dual 9 air filter. Higher performance, extended life (3-4 times longer), lower total cost and increased containment collection.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

Most people understand air pollution and poor air quality are issues that are important, but it often remains an abstract concept until it affects them directly. But food and beverage contamination grabs people's attention.