Make superior cleanroom filtration a critical component of manufacturing flat panel displays. Comply with strict air cleanliness standards while improving your yields and lowering costs.

The flat panel display (FPD) market is highly competitive and technologically complex. It’s driving manufacturers to develop higher resolution displays, new fabrication technologies and more cost-effective production processes.

As the demand for higher resolutions increases, contamination control in air, gas and liquid processes is more critical than ever. This is because smaller and smaller contaminants must be controlled at a finer level. And the probability of getting particle deposition on large display surfaces is high during key process steps.

Because of the enormous size of most FPD factories and the air volumes involved, contamination control optimization and energy savings remain a key priority for the industry. Protection of worker health is also a key concern due to the extensive use of solvents in LED and OLED manufacturing processes.

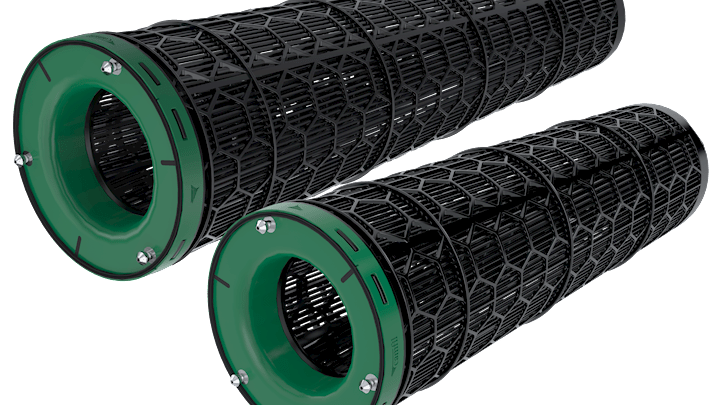

Camfil’s HEPA and ULPA filters are 100% quality inspected and ensure 100% compliance to cleanroom air quality standards. Our software packages, including life cycle cost (LCC), cleanroom optimization (CREO) and airborne molecular contamination (AMC), help you optimize your environment and achieve the best total cost of ownership.

When you choose the right solutions from our wide range of innovative, energy-efficient filters, you can gain tremendous energy savings – up to hundreds of thousands of dollars per year and facility. We bring our proven track record in AMC filtration for semiconductor manufacturing to FPD applications, offering solutions that target different types of contaminants in different process steps.

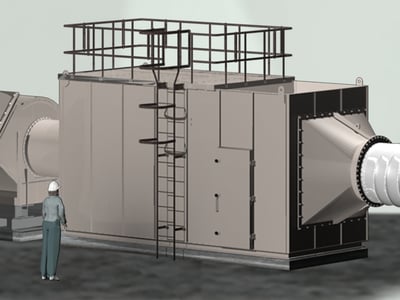

Finally, Camfil exhaust systems are able to control high concentrations of particles and chemicals often released by the large process equipment used in FPD manufacturing.

Whatever your cleanroom filtration requirements, Camfil provides display manufacturers with the technology and expertise needed to improve display quality, reduce product yield losses, minimize downtime and increase profitability.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Recirculation air units are used to provide clean and tempered air to facilities as a complement or substitute to ceiling systems and fan filter units. Recirculated air needs filtration for protecting people, processes and products.

Microelectronic processes in cleanrooms or mini-environments require protection from particles and molecular gaseous contaminants. Processes include lithography, coater developers, etch, diffusion, metallization, thin films, ion implantation, inspection tools and reticle stockers.

Air handling units that provide conditioned outdoor air to industries are a critical parts of facility systems, to create room over-pressure and compensate for exhaust air. Make up air needs proper filtration for protecting coils and ducts, people, processes and products.

Cleanroom ceilings are designed to provide high protection levels against molecules (gas phase), nanoparticles and particles for cleanroom equipment, processes and manufactured products. Ceilings use laminar or turbulent air flows depending on the cleanroom design.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studies

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverage