Protect the health and safety of workers and your food processing equipment from indoor and outdoor sources of air contamination with tailored solutions for food processing.

At Camfil, we take food safety compliance and human health seriously. Backed by high standards of research, development and quality assurance, our pioneering air filters and cleanroom solutions for the food industry can help you comply with increasingly tough food hygiene and safety regulations.

Camfil's range of filters offer food manufacturers peace of mind. They meet the strictest regulations in the food industry. Plus, they give you high energy efficiency and a lower total cost of ownership.

Food safety requires a team of dedicated people working to ensure what we eat and drink is safe. This team, following HACCP guidelines and principles, will inevitably identify hazards from the necessary airflow in a processing facility. Many of these hazards can be controlled through an analysis of the HVAC system which includes careful evaluation of the air filters.

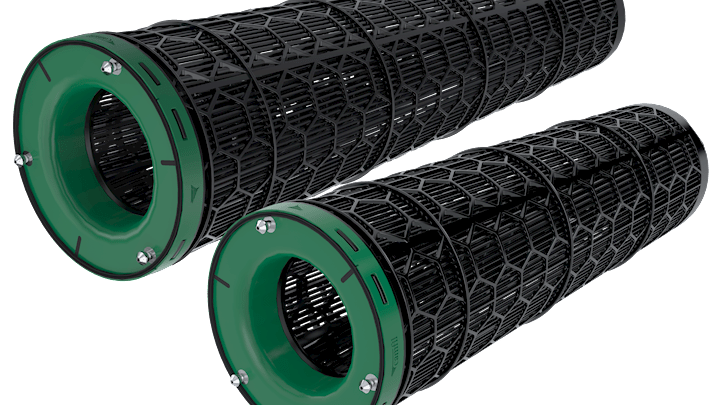

Dust collectors safely handle exhaust air from food processing and packaging applications, therefore improving the IAQ, preventing cross-contamination and reducing the nuisance dust in the workplace.

High air quality is crucial for product quality and safety in food and beverage production. The hygiene zones where the AHU operates should determine which AHU products are chosen.

Low-care areas include areas where production and product handling do not occur. Camfil recommends products that adhere to EN 16798 to best protect the health of your building occupants. For office spaces, dispatch areas.

In high-care areas, equipment needs to be protected and contamination minimized before products enter a high-hygiene area. High-care areas need high airflow and positive pressure environments. For ready-to-eat production, access corridors.

In high-hygiene areas, products requiring the highest hygiene levels undergo final processing and packaging. Here, you need the highest air quality to effectively eliminate all contamination hazards during production, cooking and packaging.

Medium-care areas, where raw material is stored, need to be kept clean to protect against product contamination. These areas include changing/gowning areas, packaging, warehousing, and plant entrances.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studies

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageIn the realm of controlled environments, where precision, purity, and protection are paramount, high-efficiency particulate air (HEPA) filters emerge as unsung heroes

It is common that meat processing factories are susceptible to the spread of airborne viruses and microbes. Temperature and humidity requirements along with the production processes lend to the survival of airborne microbes and viruses.

Often the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Processes in manufacturing facilities often generate dust and fumes which for example can pose health risks for your operators or compromise the quality and safety of your products. Determining the right capture and filtration solution helps to protect against the main risks of uncontrolled emissions and thus to create safe work environments.

Tonnies Meat Processing Facility - Boosts Air Quality Standards in the Right Places

The new Absolute VG HEPA air filter is all about making your life simpler, safer and more eco friendly. This is achieved by offering you filters that are extremely light-weight, robust and easy to handle. Filters that provide world-leading protection for your operations.

The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Air is a vital ingredient in food and beverage production. Protecting your production process and final product has never been easier.

A commercial bakery eliminates airborne pollutants and dust, improving safety, reducing downtime and lessening the risk of cross-contamination.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

Case Study: Filter Savings At Frozen Food Manufacturer. Three air handling units supplied air to critical processing areas in one of the USA's largest frozen food manufacturing facilities. The pre and final filter combination saved the plant over $33,000 per year.