Don’t choke off your business. Minimize the impact of contaminated air on surrounding communities and personnel, and the effects of corrosion on equipment, with Camfil’s gas, odor and corrosion control solutions for wastewater treatment plants.

The rising global population and global warming are combining to put extreme demands on clean water supplies. Wastewater treatment plants are critical infrastructure assets in most parts of the world.

Severe odor issues are a common problem at most wastewater treatment plants. And as cities increase in size and the protection of green spaces becomes more important, these plants are increasingly being located closer to areas of high population density. The odors are more than just a simple nuisance for your plant and the surrounding communities: they can have a huge impact on the health and safety of plant personnel and your treatment system equipment.

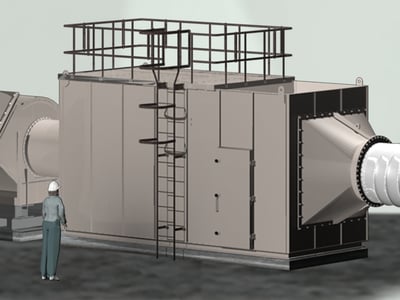

Unlike previous constructions, some of which were in remote green locations, modern wastewater treatment plants are enclosed as much as possible and in some cases built partially or totally underground, often close to cities.

Enclosure helps to contain odors – but it creates different problems. In particular, enclosure can lead to an accumulation of methane, an odorless yet explosive gas. So enclosed spaces must be ventilated to maintain the methane concentration at a safe level. When the ventilation air is exhausted to atmosphere, the gases responsible for the characteristic foul odor are also released. Odor control solutions are required in the exhaust air system.

A complex mixture of gases is responsible for the odor. The most notorious gases are hydrogen sulfide (the “rotten egg smell”, H2S) and mercaptans, but the foul air will also contain other organo-sulfur, ammonia (NH3) and organo-nitrogen gases.

In wastewater treatment facilities, the release of acidic gases also poses a problem. If these gases are not controlled in the supply air to control rooms, they will damage electrical gear used to regulate the complex array of process equipment such as pumps and penstocks.

Luckily, molecular filtration provides solutions for the problems associated with both contaminated exhaust and supply air experienced at treatment plants. Here are some of the benefits.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Many industries rely on electronic and electrical control equipment for safe and efficient operation. To avoid unscheduled breakdowns, the equipment must be protected from corrosion originating from chemicals used in their manufacturing processes.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studiesOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Electronics and optics Commercial and public buildings Manufacturing and machinery Standard and regulations Sustainability Food and beverage Life science and healthcareThe wastewater undergoes a long process at Middelfart Wastewater, where the wastewater is treated and at the end of the process it eventually becomes purified water which is then released to the sea surrounding Middelfart. In addition, the byproducts biogas is converted to electricity and heat as well as bio-fertilizer that is being used on farmers’ fields.