Improve your process yield with complete solutions for advanced semiconductor manufacturing.

In semiconductor fabs, microcontamination can pose massive problems. Camfil offers an extensive range of solutions – particle pre-filters, HEPA and ULPA filters and AMC control solutions – to lower any cleanroom particulate and molecular concentrations to ISO Class 1 levels for particles and sub-ppb for AMC.

Airborne molecular contamination (AMC) presents a special challenge to semiconductor manufacturing in small dimensions. The undesired chemical reactions of acids, bases, organics, refractories and dopants can affect wafer surfaces and process equipment optics to create defects during chip production and reduced equipment and tool efficiency.

AMC is steadily becoming more important in critical cleanroom manufacturing processes. As specifications become more demanding and device sizes shrink, process control faces tremendous pressure. Wafers can spend an entire month inside a factory, undergoing hundreds of processes before being shipped in a final product. Any tiny contamination impact in this process chain can have serious consequences for the fab’s overall yield.

Another challenge lies in the generalization of larger wafer dimensions, which drives up the cost of individual wafers and increases the need for nanoparticle and AMC protection at the tool level. Additionally, the rising costs for defect-free masks used in EUV and multi-patterning DUV lithography are putting pressure on contamination control systems for facilities as well as mini-environments like inspection equipment and mask stockers.

Camfil solutions provide field- and lab-proven protection in semiconductor manufacturing environments, including lithography, etch, diffusion, metallization, thin films, ion implantation, inspection tools, and reticle or wafer storage areas.

Camfil’s particle pre-filter range ensures the lowest energy usage in make-up air handling units while protecting HEPA filters from clogging and without releasing Boron. Camfil HEPA and ULPA filters are designed to release the lowest possible amounts of organic contaminants (so-called low outgassing), following years of developments of adhesives and media chemical properties. Exhaust systems for wafer cutting as well as gas scrubbers for general exhaust back-up systems protect the environment from process contamination.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Microelectronic processes in cleanrooms or mini-environments require protection from particles and molecular gaseous contaminants. Processes include lithography, coater developers, etch, diffusion, metalization, thin films, ion implantation, inspection tools and reticle stockers.

Cleanroom ceilings are designed to provide high protection levels against molecules (gas phase), nanoparticles and particles for cleanroom equipment, processes and manufactured products. Ceilings use laminar or turbulent air flows depending on the cleanroom design.

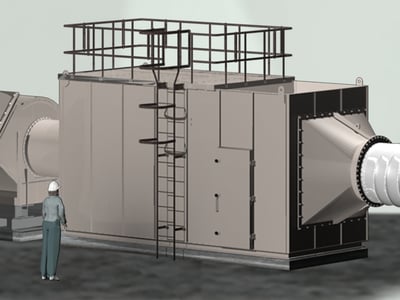

Recirculation air units are used to provide clean and tempered air to facilities, as complement or in place of ceiling systems and fan filter units. Recirculated air needs filtration for protecting people, processes and products.

Air handling units that provide conditioned outdoor air to industries are a critical parts of facility systems, to create room over-pressure and compensate for exhaust air. Make up air needs proper filtration for protecting coils and ducts, people, processes and products.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studies

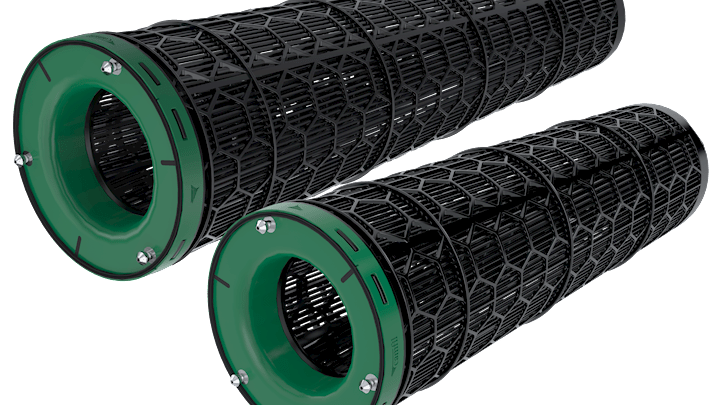

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Some of the effects of corrosion include a significant deterioration of natural and historic monuments. Air pollution causes corrosion, and it’s becoming worse worldwide. Learn how to protect your equipment.