Camfil delivers the best in filtration performance so you can deliver excellence in logistics. Camfil air cleaners help you to protect your products and your workers from harmful particles and gases.

Create a cleaner product environment with less downtime, lower energy costs, reduce environmental impact, and protect the health and safety of your workers and of the items stored in your warehouse or distribution center.

What are you looking for?

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Food and beverage Life science and healthcare Case studies

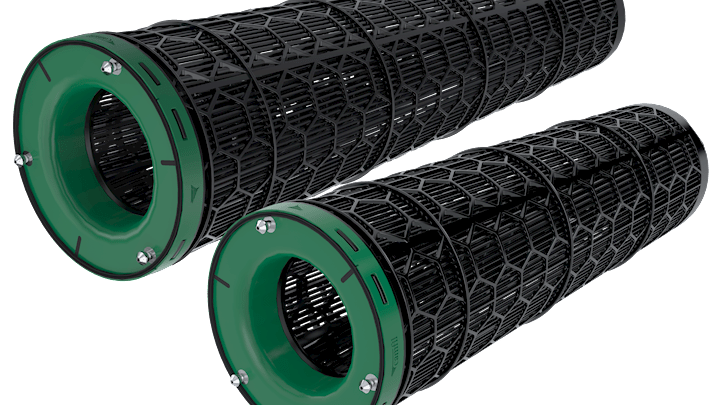

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

To answer this question, let's look at the difference between a land based gas turbine and a jet engine.

For several years, Hornsgatan has been designated Sweden's dirtiest street when it comes to air pollution. Hornsgatan is an exposed street when it comes to harmful particles in the air. How does this affect residents?

Activated carbon (also known as activated charcoal) is an exceptionally versatile material that can control the vast majority of molecules that pollute the air – that’s more than 150 million cataloged chemicals.

If you are looking to expand your knowledge on the impact of air filtration on your gas turbines and other turbomachinery, look no more!

Case Study: Air Cleaner Solves Health & Dust Issue. The DB Schenker logistics centre in Önnestad, Sweden now successfully deploys Camfil CamCleaner 6000s for filtering and purifying air in hall areas. Commissioning the CamCleaners did not require major structural alterations.

The test rig has been calibrated according to standards EN 779, ISO 16890 and ASHRAE 52.2 and was developed for air filter testing simulating the harsh climate conditions where gas turbines are often located.