空氣過濾對風能、熱能、核能或沼氣等多種發電應用均起到關鍵作用。空氣濾網對確保設備運行的安全性和效率至關重要。

市場競爭激烈,監管制度嚴格,在此情況下,創新的空氣過濾解決方案對企業的盈利能力產生巨大影響,為您打造競爭優勢。瞭解現場工作環境有助於強化進氣系統,滿足您的操作和維護需求,提高服務間隔和產出。

寻找什么?

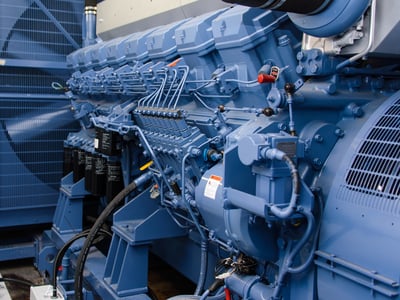

在柴油和燃氣發動機的燃燒過程中,需要防止受到元素、過熱和污染物的影響。周圍環境還需要避免高溫排氣的影響。先進的解決方案,防止任何喘振風險。

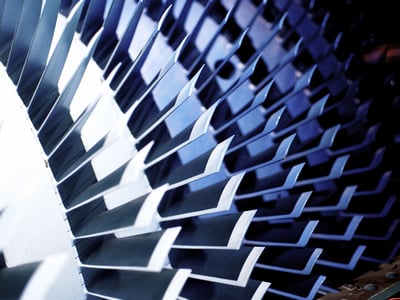

燃氣輪機是高效、靈敏的尖端設備,可用於發電或作為動力機械驅動不同生產製程。它們廣泛應用於世界各地,面臨的環境和工作環境可能大相徑庭。因此,需要對濾網解決方案進行調適,確保提供足夠的保護。

渦輪機械和電氣設備(如發電機)需要採取適當的通風冷卻措施,防止元件和溫度過高。應根據周圍環境確定通風裝置的防護等級,以防止水、鹽和其他污染物進入。

空氣壓縮機是眾多加工業的關鍵設備;這些加工業依靠高效過濾來保持長時間運行,避免停機。環境和工作環境可能大相徑庭。因此,需要對所需的濾網解決方案進行調適,確保適應您當地的條件和操作。

早在20世紀60年代初期,Camfil已開始為核電站提供解決方案。如今,匯總來自於全世界90多個工廠的經驗,我們成為放射性粉塵和氣相空氣清淨機領域的全球領導者。

風力渦輪機在惡劣的條件下運行。進氣濾網應高效且堅固,以確保較長的使用壽命,最大限度地降低能耗。

Alto Garda Power将他们的过滤系统升级为LM6000燃气轮机的两级静态系统。其优点包括阻力降低50%,最终过滤器寿命是原来的4倍,预过滤器寿命是原来的9倍等等。

Energy and Power Systems Case studies首个针对高压下透平机械进气过滤器机械完整性评估的国际测试标准

Standard and regulations Energy and Power Systems如果没有HEPA过滤器,我们将无法生产计算机、药品和许多其他当今世界必不可少的产品。但是这些高效微粒空气过滤器的历史是什么,它们是如何使用的,在哪里使用的?

C位于墨西哥的CCC Pesquaria(Central Electrica)将过滤器升级至TurboPulse™过滤器,每台发动机的退化减少了5倍,每年输出增幅高达20000MWH,额外创造了600美金的利润并减少了碳足迹。

泰国GPSC工厂将其原有的6个燃气轮机过滤器升级至康斐尔TurboPulse T12过滤器,年节省费用达到520,000美元,166000的燃料消耗,以及8800吨二氧化碳排放量,同时压缩机效率提升了3倍。

您是否知道 Camfil 擁有全系列的改裝過濾器,可用於市場上所有最常見的品牌。 Camfil 過濾器不僅設計用於工作,而且用於優化您的除塵系統性能

並不是所有購買我們產品的人都是空氣過濾方面的專家,他們也不需要成為專家。康法 (camfil)的目的是讓每個人都有機會了解我們的潔淨空氣解決方案能為他們做些什麼。

ISO發布了第一個透平機械進氣過濾器專用標準 : ISO 29461-1和ISO 29461-2。這些標準提供了測試過濾器的統一方法,使透平機械運營商能夠更輕鬆地比較和選擇進氣過濾器。

首個針對過濾器在水霧環境條件下耐受性的評級標準,體現了過濾器的耐水性。使用 ISO 29461-2, 用户們可以来判定什麼樣的渦輪機械進氣系統過濾器在潮濕環境中性能最好。

CamGT 3V-600 靜態最終過濾器和 Cam-Flo GT Hybrid 袋式空氣過濾器每年消除 6 次離線清洗,提高燃氣輪機壓縮機效率,並提高新加坡沿海熱電廠的功率輸出。

CamPure 32是一種新的理想的Camfil介質,用於厭氧過程中沼氣生產過程中硫化氫的去除。了解這個法國農場如何將高質量的化學吸收介質應用到沼氣應用中。

Dyna Mig 原來使用一個競爭對手的除塵器解決方案,該解決方案經常導致代價高昂的停機時間。 在 Camfil 的專業知識和旗艦 Camfil Gold 系列 GSX 除塵器系統的幫助下,Dyna Mig 能夠消除所有計劃外停機時間並將其加熱成本降至最低 - 並且工作更安全。

ISO29461-1 是第一個針對渦輪機械應用的空氣濾網效率標準,此標準可以幫助我們選擇正確的渦輪空氣濾網

Camfil 為容器製造商 AMG 提供了更有效的除塵和排煙系統,提供更高的過濾率。

CK Power是泰國和東盟地區領先的發電公司之一。 它運營著 Bangpa-in 熱電廠一期 (BIC1),為城市和鄰近的工業工廠提供電力。

印度最大的綜合電力公司 Tata Power Ltd 在燃氣輪機嚴重熱腐蝕和高壓降危及性能和安全後,要求 Camfil 對 Cam-Flo 袋式袋式過濾器和 CamGT 靜態空氣過濾器進行改造。

法國燃氣輪機市場的領導者 Dalkia 對各種進氣過濾器(包括 Camfil 的 Hi-Flo 預過濾器和 CamGT EPA 過濾器)進行了全國比較測試,以提高其 10 GE LM6000 燃氣輪機的發電量。

Cofely是法國燃氣蘇伊士集團(GDF Suez) 旗下的一家公司,Corely是全球領先的能源、技術和設施管理服務外包專家之一。Camfil提供City 系列空氣淨化器來改善室內空氣品質。

來自泰國鄰近社區的噪音投訴促使這些工廠評估降噪過濾系統。 CamGT 高效空氣過濾器解決方案不僅提高了噪音水平,還提高了渦輪機的可用性、改善了壓降並幫助燃氣輪機產生了更多的功率

Watson 熱電聯產廠運行 4 台 GE、Frame 7EA 發動機,為當地煉油廠生產 400 兆瓦的電力,並將多餘的電力出售給電網。工廠經理要求 Camfil 進行進氣效率、壓降和水測試。測試結果揭示了合成濾芯過濾器對燃氣輪機性能的真正影響。

並排比較顯示了更高等級的 GTC F9 燃氣輪機進氣過濾器對兩台 RB211 燃氣輪機的好處,即使在非常乾淨的農村地區也是如此。這意味著更清潔的發動機、更高的功率輸出、更少的水洗和節省燃料。

在測試顯示其水和鹽處理能力後,太平洋沿岸的一家能源廠將其 Siemens 501F 燃氣輪機過濾器升級為 CamGT 4V-300 進氣過濾器。

空氣採樣、CamLab 現場分析以及生命週期成本分析證明,CamGT EPA 過濾器不會導致渦輪機水洗停機,最終過濾器壽命延長至 5 年,降低腐蝕風險並實現最大功率輸出。

頻繁的壓力和較短的過濾器更換間隔導致了高昂的運營成本。 Camfil 的 Cam-Flo 進氣預過濾器和 CamGT EPA 空氣過濾器實現了 8000 小時使用壽命並將壓降降低 50% 的目標。

泰國最大的能源生產商 Egat North 升級到 Hi-Flo 和 CamClose 進氣預過濾器以及 CamGT 最終 EPA 空氣過濾器,將降解率降低了 70%,減少了水洗需求,每年節省約 124 萬美元.

Camfil動力系統業務為包括燃氣輪機、發電機、工業空氣壓縮機和柴油發動機在內的透平機械提供過濾和聲學解決方案。在過去的幾十年裡,渦輪機技術發生了巨大的變化。

您是否了解,98%的空氣和2%的燃料是您對渦輪機的投入最有價值的資產?如果我們告訴您100%的空氣中含有污染物,如果過濾不當會損壞您的渦輪機呢?

隨著世界範圍內保護環境意識的增強,發電、石油和天然氣行業面臨著越來越大的壓力,需要找到更環保的能源解決方案。升級工廠的進氣系統是減少碳足跡最簡單、最經濟的方法之一

位於英國薩默塞特的欣克利角 C 是最安全和最高效的核能發電機之一,屬於壓水反應堆 (PWR) 類型。 隨著數百兆瓦電力生產的規劃,過程的安全性成為一個關鍵問題。

案例分析: 沼氣中含有大量硫化氫(H2S),這種氣體會導致燃氣發動機內部的腐蝕和點蝕。在H2S含量高且易於維護的情況下,需要一種解決方案。

CamGT EPA 過濾器解決方案位於非洲科特迪瓦近海,每年可節省 Foxtrot International 3 次停機並消除鹽腐蝕,而不會影響佔地面積。