La filtrazione dell'aria gioca un ruolo fondamentale in molte applicazioni di generazione energia come quella eolica, termale, nucleare o biogas. I filtri aria sono essenziali per la sicurezza e l'efficienza dei processi.

In mercati molto competitivi e regolamentati, soluzioni innovative di filtrazione possono rappresentare un vantaggio competitivo poiché hanno un forte impatto sulla profittabilità delle operazioni. Comprendere le condizioni locali dell'impianto permette di ottimizzare il sistema di filtrazione per soddisfare le tue esigenze operative e di manutenzione, aumentare il servizio e gli output

Che cosa stai cercando?

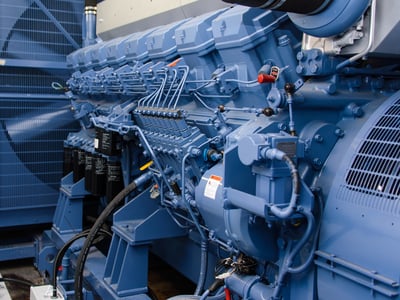

I motori diesel e a gas necessitano di protezione dagli elementi, dalle temperature eccessive e dai contaminanti durante il processo di combustione. Anche l'ambiente circostante necessita di protezione dai gas di scarico caldi. Soluzioni robuste proteggono da qualsiasi rischio di sovratensione.

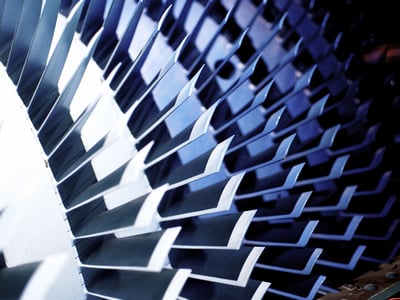

Le turbine a gas sono macchine altamente efficienti e sensibili che possono essere utilizzate per generare elettricità o come azionamento meccanico per alimentare diversi processi. Sono utilizzate in tutto il mondo in condizioni ambientali e operative che possono variare drasticamente. Ecco perché la soluzione di filtrazione deve essere adattata per offrire una protezione adeguata.

Turbomacchine e apparecchiature elettriche come i generatori necessitano di protezione dagli elementi e dalle temperature eccessive con una ventilazione appropriata per il raffreddamento. Il livello di protezione dell'unità di ventilazione deve essere personalizzato in base all'ambiente circostante per proteggere da acqua, sale e altri contaminanti.

I compressori ad aria sono essenziali per molte industrie di trasformazione che si affidano a una filtrazione efficiente per rimanere operative per periodi di tempo prolungati, senza arresti. Le condizioni ambientali e operative possono variare drasticamente. Ecco perché la soluzione di filtrazione richiesta deve essere adattata alle condizioni e alle operazioni del sito locale.

Camfil fornisce soluzioni per centrali nucleari fin dai primi anni '60. Oggi siamo leader mondiali nella filtrazione di particolato nucleare e in fase gassosa, con un'esperienza in oltre 90 impianti in tutto il mondo.

Le turbine eoliche operano in alcune delle condizioni più difficili. I filtri di ingresso dell'aria devono essere altamente efficienti e robusti per garantire una lunga durata e ridurre al minimo il consumo di energia.

Lo sapevi che Camfil ha una gamma completa di filtri retrofit che possono essere utilizzati in tutte le marche più comuni sul mercato? I filtri Camfil non sono solo progettati per funzionare, ma per ottimizzare le prestazioni dei tuoi sistemi di depolverazione

Manufacturing and machinery Turbomacchine Food and beverage Life science and healthcareIl primo standard internazionale di test per riportare l’integrità meccanica dei filtri di ingresso aria per turbomacchine in condizioni di pressione elevata

Standard e normative TurbomacchineCCC Pesquería in Messico è passata ai filtri TurboPulse T10, riducendo di 5 volte la degradazione di potenza, aumentando la produzione annuale di circa 20.000 MWh, aggiungendo oltre 600.000 dollari di profitto annuale e riducendo l'impronta di carbonio.

Without HEPA filters, we would not be able to manufacture computers, medicine and many other products that are essential in today’s world. But what is the history of these High Efficiency Particulate Air filters and how and where are they used?

TurboPulse, la più recente tecnologia a impulsi per il 21° secolo, adotta un approccio moderno alla progettazione del filtro con molte nuove funzionalità progettate per migliorare la durata del filtro e le prestazioni degli impulsi per le turbomacchine.

ISO 29461: Standard per filtri di ingresso aria per turbomacchine

Il primo standard di test internazionale che valuta la resistenza di un filtro in ambienti con nebbia e foschia e determina la sua resistenza alla penetrazione dell’acqua.

La qualità dell'aria è fondamentale per le prestazioni e la durata delle tue turbine a gas. Questa infografica mostra l'impatto della filtrazione, le cause delle scarse prestazioni, la mitigazione e il nuovo standard di filtrazione ISO 29461.

Per la prima volta, esiste uno standard di efficienza di filtrazione specifico per le turbine a gas. Scopri come ISO29461-1 può aiutarti a selezionare i filtri corretti per ogni applicazione di turbomacchine.

ISO 29461-1 è il primo standard di test internazionale per riportare l'efficienza per l'intera gamma di filtri di di ingresso aria per turbine a gas, compressori e altre applicazioni turbomacchine.

Non tutte le persone che acquistano i nostri prodotti sono esperte in filtrazione dell’aria, e nemmeno è necessario che lo siano. Lo scopo di Camfil City è di offrire a tutti la possibilità di apprendere le basi di ciò che le nostre soluzioni per l’aria pulita possono fare per loro.

Le acque reflue subiscono un lungo processo a Middelfart Wastewater, dove le acque reflue vengono trattate e alla fine del processo diventano acqua purificata che viene quindi rilasciata nel mare che circonda Middelfart. Inoltre, il biogas dei sottoprodotti viene convertito in elettricità e calore, nonché in biofertilizzante utilizzato nei campi degli agricoltori.

Dyna Mig had a competitor dust collector solution that regularly caused costly downtime. With the help of Camfil’s expertise and a flagship Camfil Gold Series GSX dust collector system, Dyna Mig was able to eliminate all unscheduled downtime and cut their heating costs to a minimum – as well as work safer.

La linea dei filtri per l’aria CamGT è stata potenziata per massimizzare la potenza, i profitti e i tempi di attività della tua turbina a gas.

Il filtro per l'aria a pannello CamClose è progettato per i sistemi di ingresso aria delle turbine a gas per fornire operazioni senza problemi, prestazioni stabili e una maggiore protezione.

L'acido sofidrico è uno dei principali contaminanti che devono essere eliminati dalla produzione di biogas nell'ambito della purificazione. Ciò può essere ottenuto utilizzando filtri a carbone attivo che rimuovono gas e odori nocivi dal processo.

CamPure 32 è il nuovo media Camfil ideale per la rimozione dell'acido solfidrico durante la produzione di biogas in un processo anaerobico. Scopri come questa azienda agricola in Francia ha applicato il media chimico adsorbente di alta qualità alla loro applicazione biogas.

I filtri finali statici CamGT 3V-600 e i filtri a tasche morbide Cam-Flo GT Hybrid eliminano 6 lavaggi offline all’anno, migliorano l’efficienza del compressore della turbina a gas, e aumentano la potenza erogata di una centrale elettrica di cogenerazione costiera di Singapore.

Case Study: In the gas turbine of a power plant in east China, Camfil China upgraded its pulse filter and retrofitted the prefilter from panel type to pocket type, new solution have been continuously running for more than 9500EOH, while original solution’s lifetime to pressure drop alarm value is less than 2000EOH.

Camfil Power Systems (PS) fornisce soluzioni di filtraggio e acustiche per turbomacchine comprese turbine a gas, generatori, compressori d'aria industriali e motori diesel. La tecnologia delle turbomacchine si è evoluta enormemente negli ultimi decenni.

Il carbone attivo è un materiale eccezionalmente versatile che può trattenere la stragrande maggioranza delle molecole che inquinano l'aria, ovvero oltre 150 milioni di sostanze chimiche catalogate.

Con una richiesta crescente di pratiche più ecologiche, e con l’aumento dei costi operativi, è diventato essenziale che gli operatori delle turbine a gas riducano il loro carbon footprint. L’upgrade dei sistemi di filtrazione aria è uno dei modi più semplici ed economici per soddisfare queste richieste, migliorando al tempo stesso l’operatività.

Fai un upgrade alla filtrazione GT per ridurre le carbon emissions per MWh prodotto

Il processo del biogas è fondamentale in quanto rilascia gas fortemente contaminati che possono causare corrosione del motore e abrasione delle attrezzature, causando tempi di fermo non programmati per la manutenzione e la riparazione, con conseguente perdita di produzione e profitto. Fortunatamente, esistono diversi modi per risolvere la filtrazione molecolare negli impianti di biogas con diversi tipi di media filtranti in letti profondi.

Hinkley Point C nel Somerset, Regno Unito, è tra i generatori di energia nucleare più sicuri ed efficienti, ed è un tipo di reattore ad acqua pressurizzata (PWR). Con centinaia di megawatt di produzione elettrica in fase di pianificazione, la sicurezza del processo diventa una preoccupazione fondamentale.

Se vuoi ampliare le tue conoscenze sull’impatto della filtrazione dell’aria sulle tue turbine a gas e altre turbomacchine, non cercare altro!

The Watson Cogeneration Plant operates 4 GE, Frame 7EA engines and produces 400 MW for local refineries and sells excess electricity to the grid. The Plant Manager requested air intake efficiency, pressure drop, and water tests from Camfil. The test results revealed the true impact of the synthetic cartridge filters on gas turbine performance.

A side by side comparison shows the benefits of higher grade GTC F9 gas turbine air intake filters for two RB211 gas turbines, even in very clean rural areas. It means a cleaner engine, higher power output, fewer water washes, and fuel savings.

An energy plant on the pacific coast upgrades their Siemens 501F gas turbine filtration to the CamGT 4V-300 air intake filters after tests show its water and salt handling capabilities.

Air sampling, CamLab on-site analysis, as well as a Life Cycle Cost analysis show that the CamGT EPA filters will result in no shutdowns for turbine water washes, final filter shutdown extended to 5 years, decreased risk of corrosion and maximum power output.

Frequent pressure and short filter replacement intervals led to high operational costs. Camfil's Cam-Flo air intake pre-filters and CamGT EPA air filters met their goal of 8000 hours of life and reduced pressure drop by 50%.

Egat North, the largest energy producer in Thailand, upgraded to Hi-Flo and CamClose air intake pre-filters as well as CamGT final EPA air filters and lowered degradation by 70%, reduced water wash requirements, and saved approximately $1.24M USD per year.

Protect your gas turbine from ice formation during high humidity and low temperatures. Insufficient icing protection may result in inlet filter system issues and ice formation at the turbine inlet.

To answer this question, let's look at the difference between a land based gas turbine and a jet engine.

Case Study: The BioGas produced is heavily laden with H2S (hydrogen sulphide), a gas that can cause corrosion and pitting inside the gas engine. A solution was required where a high level of abatement of H2S was possible and an easy filter media maintenance.

Located offshore Ivory Coast, Africa, the CamGT EPA filter solution saves Foxtrot International 3 shutdowns per year and eliminates salt corrrosion, without compromising on footprint.

Tata Power Ltd, India's largest integrated power company requests Camfil for a Cam-Flo pocket bag filter and CamGT static air filter retrofit after heavy hot corrosion in the gas turbine and high pressure drop jeopardized performance and safety.

Dalkia, a leader in the French gas turbine market, launched a national comparative test for various air intake filters, including Camfil's Hi-Flo pre-filters and CamGT EPA filters, to increase power production for their 10 GE LM6000 gas turbines.

Case Study: Clean Air For Cofely United Kingdom. Cofely, a GDF Suez company, is one of the leading experts in energy, technology and facilities management services with business outsourcing. Camfil provides City air purifiers to improve IAQ.

Il principale produttore indipendente di energia in Thailandia gestisce centrali a ciclo combinato a turbine a gas con un output di 1.600MW ciascuna, con quattro turbine a gas M701F4, due turbine a vapore e sei generatori.

Gas Turbine Application: Do you operate in a coastal or offshore site? Unfortunately, you probably have to deal with corrosion related issues. You can, however, operate corrosion-free if you take the right measures.

Turbomachinery: Air inlet filtration systems should be designed to suit the environment. Because of market pressures, a general design has been used in widely varying environment conditions. Before making your purchase, get an assessment.

Applicazione Turbine a Gas: La qualità dei filtri aria è essenziale per le prestazioni ottimali delle turbine a gas. Proteggere la turbina con soluzioni di filtrazione specifiche per il tuo sito garantisce profitti elevati.