A panel-type molecular filter with a customizable metal frame fitted with high cleanliness embedded adsorbents for the removal of VOCs, acids, bases, and dopants. Specially designed to be fitted on top of HEPA/ULPA filters, fan filter units (FFU) in cleanroom ceilings, mini environments or process equipment. The filter can be designed to adsorb multiple contaminant types.

To answer this question, let's look at the difference between a land based gas turbine and a jet engine.

Energy and Power Systems

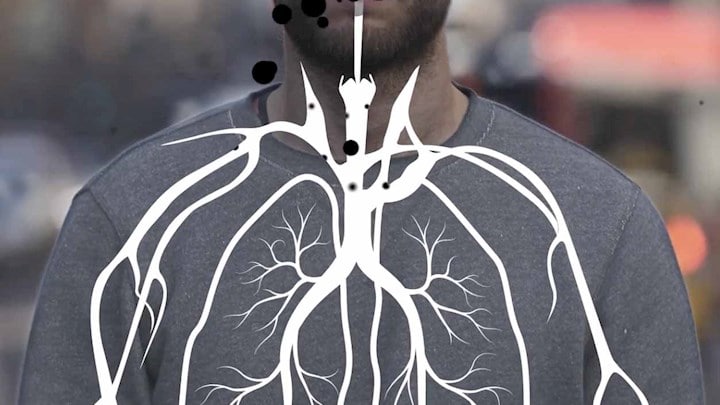

For several years, Hornsgatan has been designated Sweden's dirtiest street when it comes to air pollution. Hornsgatan is an exposed street when it comes to harmful particles in the air. How does this affect residents?

Air quality Case studiesIf you are looking to expand your knowledge on the impact of air filtration on your gas turbines and other turbomachinery, look no more!

The test rig has been calibrated according to standards EN 779, ISO 16890 and ASHRAE 52.2 and was developed for air filter testing simulating the harsh climate conditions where gas turbines are often located.