Anti-icing systems for gas turbines or inlet heating systems are used either to reduce the risk of ice formation in the turbine bellmouth or to avoid filter clogging from icing or snow formation. Icing on the filters raises the pressure drop of the system, diminishing turbine efficiency and power output. This can also lead to the turbine shutting down. The risk of ice formation in the turbine bellmouth/compressor could result in damage to the turbine internals. Anti-icing/air inlet heating systems are critical in environments where ice formation may occur. Solutions include: pulse cartridge systems, heating coils, hot air ventilation, hot air exhaust, hot air compressed bleed air anti-icing system, infrared heating, electrical resistance and heated CamVanes. Read about these options in more detail here. Link: https://www.camfil.com/damdocuments/49772/1221753/guide-anti-icing-air-inlet-heating-eng.pdf

To answer this question, let's look at the difference between a land based gas turbine and a jet engine.

Energy and Power Systems

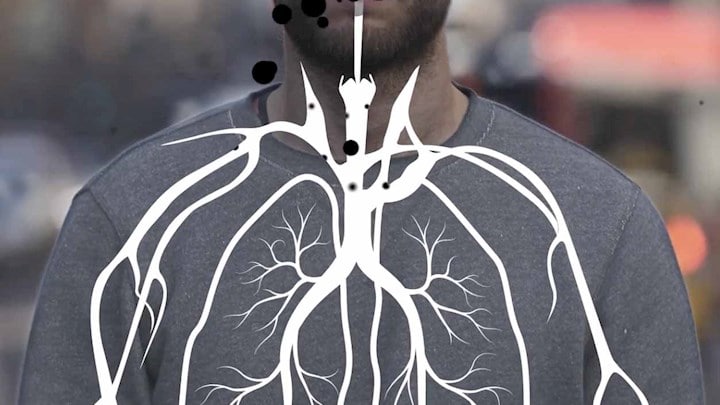

For several years, Hornsgatan has been designated Sweden's dirtiest street when it comes to air pollution. Hornsgatan is an exposed street when it comes to harmful particles in the air. How does this affect residents?

Air quality Case studiesIf you are looking to expand your knowledge on the impact of air filtration on your gas turbines and other turbomachinery, look no more!

The test rig has been calibrated according to standards EN 779, ISO 16890 and ASHRAE 52.2 and was developed for air filter testing simulating the harsh climate conditions where gas turbines are often located.