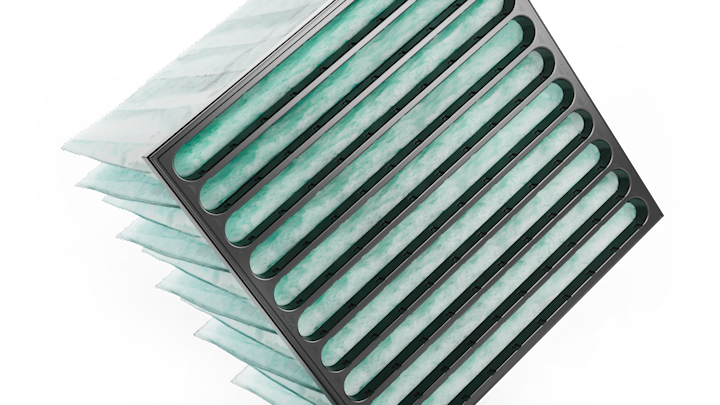

The premium range of glass fiber bag filters with steel frame. These filters have the highest energy efficiency and longest operating life. With their low pressure drops and high dust holding capacites, lowest labour cost thanks to less frequent filter changes can be achieved. Available in all efficiencies according to ISO16890.

| Item Type | ISO 16890 | Filter Class EN779 | Width (mm) | Height (mm) | Depth (mm) | Airflow (m3/h) | Pressure drop Initial (Pa) | Energy (kWh/year) | Energy Class (Eurovent) |

|---|---|---|---|---|---|---|---|---|---|

| 1060 592x592x520-10 | ePM10 60% | M5 | 592 | 592 | 520 | 3400 | 40 | 568 | A |

| 1060 490x592x520-8 | ePM10 60% | M5 | 490 | 592 | 520 | 2800 | 40 | A | |

| 1060 287x592x520-5 | ePM10 60% | M5 | 287 | 592 | 520 | 1700 | 40 | A | |

| 1060 287x287x520-5 | ePM10 60% | M5 | 287 | 287 | 520 | 800 | 40 | A | |

| 1060 592x490x520-10 | ePM10 60% | M5 | 592 | 490 | 520 | 2800 | 40 | A | |

| 1060 592x287x520-10 | ePM10 60% | M5 | 592 | 287 | 520 | 1700 | 40 | A | |

| 1060 287x892x520-5 | ePM10 60% | M5 | 287 | 892 | 520 | 2500 | 40 | A | |

| 1060 592x892x520-10 | ePM10 60% | M5 | 592 | 892 | 520 | 5000 | 40 | A | |

| 1060 490x892x520-8 | ePM10 60% | M5 | 490 | 892 | 520 | 4100 | 40 | A | |

| 2550 592x592x640-12 | ePM2,5 50% | M6 | 592 | 592 | 640 | 3400 | 55 | 748 | A |

| 2550 490x592x640-10 | ePM2,5 50% | M6 | 490 | 592 | 640 | 2800 | 55 | A | |

| 2550 287x592x640-6 | ePM2,5 50% | M6 | 287 | 592 | 640 | 1700 | 55 | A | |

| 2550 287x287x640-6 | ePM2,5 50% | M6 | 287 | 287 | 640 | 800 | 55 | A | |

| 2550 592x287x640-12 | ePM2,5 50% | M6 | 592 | 287 | 640 | 1700 | 55 | A | |

| 2550 592x490x640-12 | ePM2,5 50% | M6 | 592 | 490 | 640 | 2800 | 55 | A | |

| 2550 592x892x640-12 | ePM2,5 50% | M6 | 592 | 892 | 640 | 5000 | 55 | A | |

| 2550 490x892x640-10 | ePM2,5 50% | M6 | 490 | 892 | 640 | 4100 | 55 | A | |

| 2550 287x892x640-6 | ePM2,5 50% | M6 | 287 | 892 | 640 | 2500 | 55 | A | |

| 2550 592x592x520-10 | ePM2,5 50% | M6 | 592 | 592 | 520 | 3400 | 65 | 992 | C |

| 2550 490x592x520-8 | ePM2,5 50% | M6 | 490 | 592 | 520 | 2800 | 65 | C | |

| 2550 287x592x520-5 | ePM2,5 50% | M6 | 287 | 592 | 520 | 1700 | 65 | C | |

| 2550 287x287x520-5 | ePM2,5 50% | M6 | 287 | 287 | 520 | 800 | 65 | C | |

| 2550 592x287x520-10 | ePM2,5 50% | M6 | 592 | 287 | 520 | 1700 | 65 | C | |

| 2550 592x490x520-10 | ePM2,5 50% | M6 | 592 | 490 | 520 | 2800 | 65 | C | |

| 2550 592x892x520-10 | ePM2,5 50% | M6 | 592 | 892 | 520 | 5000 | 65 | C | |

| 2550 490x892x520-8 | ePM2,5 50% | M6 | 490 | 892 | 520 | 4100 | 65 | C | |

| 2550 287x892x520-5 | ePM2,5 50% | M6 | 287 | 892 | 520 | 2500 | 65 | C | |

| 2550 592x592x370-12 | ePM2,5 50% | M6 | 592 | 592 | 370 | 3400 | 70 | 1280 | C |

| 2550 490x592x370-10 | ePM2,5 50% | M6 | 490 | 592 | 370 | 2800 | 70 | C | |

| 2550 287x592x370-6 | ePM2,5 50% | M6 | 287 | 592 | 370 | 1700 | 70 | C | |

| 2550 287x287x370-6 | ePM2,5 50% | M6 | 287 | 287 | 370 | 800 | 70 | C | |

| 2550 592x287x370-12 | ePM2,5 50% | M6 | 592 | 287 | 370 | 1700 | 70 | C | |

| 2550 592x490x370-12 | ePM2,5 50% | M6 | 592 | 490 | 370 | 2800 | 70 | C | |

| 2550 592x892x370-12 | ePM2,5 50% | M6 | 592 | 892 | 370 | 5000 | 70 | C | |

| 2550 490x892x370-10 | ePM2,5 50% | M6 | 490 | 892 | 370 | 4100 | 70 | C | |

| 2550 287x892x370-6 | ePM2,5 50% | M6 | 287 | 892 | 370 | 2500 | 70 | C | |

| 0160 592x592x640-12 | ePM1 60% | F7 | 592 | 592 | 640 | 3400 | 65 | 803 | A+ |

| 0160 490x592x640-10 | ePM1 60% | F7 | 490 | 592 | 640 | 2800 | 65 | A+ | |

| 0160 287x592x640-6 | ePM1 60% | F7 | 287 | 592 | 640 | 1700 | 65 | A+ | |

| 0160 287x287x640-6 | ePM1 60% | F7 | 287 | 287 | 640 | 800 | 65 | A+ | |

| 0160 592x287x640-12 | ePM1 60% | F7 | 592 | 287 | 640 | 1700 | 65 | A+ | |

| 0160 592x490x640-12 | ePM1 60% | F7 | 592 | 490 | 640 | 2800 | 65 | A+ | |

| 0160 592x892x640-12 | ePM1 60% | F7 | 592 | 892 | 640 | 5000 | 65 | A+ | |

| 0160 490x892x640-10 | ePM1 60% | F7 | 490 | 892 | 640 | 4100 | 65 | A+ | |

| 0160 287x892x640-6 | ePM1 60% | F7 | 287 | 892 | 640 | 2500 | 65 | A+ | |

| 0160 592x592x520-10 | ePM1 60% | F7 | 592 | 592 | 520 | 3400 | 75 | 943 | A |

| 0160 490x592x520-8 | ePM1 60% | F7 | 490 | 592 | 520 | 2800 | 75 | A | |

| 0160 287x592x520-5 | ePM1 60% | F7 | 287 | 592 | 520 | 1700 | 75 | A | |

| 0160 287x287x520-5 | ePM1 60% | F7 | 287 | 287 | 520 | 800 | 75 | A | |

| 0160 592x287x520-10 | ePM1 60% | F7 | 592 | 287 | 520 | 1700 | 75 | A | |

| 0160 592x490x520-10 | ePM1 60% | F7 | 592 | 490 | 520 | 2800 | 75 | A | |

| 0160 592x892x520-10 | ePM1 60% | F7 | 592 | 892 | 520 | 5000 | 75 | A | |

| 0160 490x892x520-8 | ePM1 60% | F7 | 490 | 892 | 520 | 4100 | 75 | A | |

| 0160 287x892x520-5 | ePM1 60% | F7 | 287 | 892 | 520 | 2500 | 75 | A | |

| 0160 592x592x370-12 | ePM1 60% | F7 | 592 | 592 | 370 | 3400 | 95 | 1275 | C |

| 0160 490x592x370-10 | ePM1 60% | F7 | 490 | 592 | 370 | 2800 | 95 | C | |

| 0160 287x592x370-6 | ePM1 60% | F7 | 287 | 592 | 370 | 1700 | 95 | C | |

| 0160 287x287x370-6 | ePM1 60% | F7 | 287 | 287 | 370 | 800 | 95 | C | |

| 0160 592x287x370-12 | ePM1 60% | F7 | 592 | 287 | 370 | 1700 | 95 | C | |

| 0160 592x490x370-12 | ePM1 60% | F7 | 592 | 490 | 370 | 2800 | 95 | C | |

| 0160 592x892x370-12 | ePM1 60% | F7 | 592 | 892 | 370 | 5000 | 95 | C | |

| 0160 490x892x370-10 | ePM1 60% | F7 | 490 | 892 | 370 | 4100 | 95 | C | |

| 0160 287x892x370-6 | ePM1 60% | F7 | 287 | 892 | 370 | 2500 | 95 | C | |

| 0170 592x592x640-12 | ePM1 70% | F7 | 592 | 592 | 640 | 3400 | 80 | 967 | A |

| 0170 490x592x640-10 | ePM1 70% | F7 | 490 | 592 | 640 | 2800 | 80 | A | |

| 0170 287x592x640-6 | ePM1 70% | F7 | 287 | 592 | 640 | 1700 | 80 | A | |

| 0170 287x287x640-6 | ePM1 70% | F7 | 287 | 287 | 640 | 800 | 80 | A | |

| 0170 592x287x640-12 | ePM1 70% | F7 | 592 | 287 | 640 | 1700 | 80 | A | |

| 0170 592x490x640-12 | ePM1 70% | F7 | 592 | 490 | 640 | 2800 | 80 | A | |

| 0170 592x892x640-12 | ePM1 70% | F7 | 592 | 892 | 640 | 5000 | 80 | A | |

| 0170 490x892x640-10 | ePM1 70% | F7 | 490 | 892 | 640 | 4100 | 80 | A | |

| 0170 287x892x640-6 | ePM1 70% | F7 | 287 | 892 | 640 | 2500 | 80 | A | |

| 0170 592x592x520-10 | ePM1 70% | F7 | 592 | 592 | 520 | 3400 | 100 | 1196 | B |

| 0170 490x592x520-8 | ePM1 70% | F7 | 490 | 592 | 520 | 2800 | 100 | B | |

| 0170 287x592x520-5 | ePM1 70% | F7 | 287 | 592 | 520 | 1700 | 100 | B | |

| 0170 287x287x520-5 | ePM1 70% | F7 | 287 | 287 | 520 | 800 | 100 | B | |

| 0170 592x287x520-10 | ePM1 70% | F7 | 592 | 287 | 520 | 1700 | 100 | B | |

| 0170 592x490x520-10 | ePM1 70% | F7 | 592 | 490 | 520 | 2800 | 100 | B | |

| 0170 592x892x520-10 | ePM1 70% | F7 | 592 | 892 | 520 | 5000 | 100 | B | |

| 0170 490x892x520-8 | ePM1 70% | F7 | 490 | 892 | 520 | 4100 | 100 | B | |

| 0170 287x892x520-5 | ePM1 70% | F7 | 287 | 892 | 520 | 2500 | 100 | B | |

| 0170 592x592x370-12 | ePM1 70% | F7 | 592 | 592 | 370 | 3400 | 130 | 1677 | D |

| 0170 490x592x370-10 | ePM1 70% | F7 | 490 | 592 | 370 | 2800 | 130 | D | |

| 0170 287x592x370-6 | ePM1 70% | F7 | 287 | 592 | 370 | 1700 | 130 | D | |

| 0170 287x287x370-6 | ePM1 70% | F7 | 287 | 287 | 370 | 800 | 130 | D | |

| 0170 592x287x370-12 | ePM1 70% | F7 | 592 | 287 | 370 | 1700 | 130 | D | |

| 0170 592x490x370-12 | ePM1 70% | F7 | 592 | 490 | 370 | 2800 | 130 | D | |

| 0170 592x892x370-12 | ePM1 70% | F7 | 592 | 892 | 370 | 5000 | 130 | D | |

| 0170 490x892x370-10 | ePM1 70% | F7 | 490 | 892 | 370 | 4100 | 130 | D | |

| 0170 287x892x370-6 | ePM1 70% | F7 | 287 | 892 | 370 | 2500 | 130 | D | |

| 0185 592x592x640-12 | ePM1 85% | F9 | 592 | 592 | 640 | 3400 | 125 | 1520 | C |

| 0185 490x592x640-10 | ePM1 85% | F9 | 490 | 592 | 640 | 2800 | 125 | C | |

| 0185 287x592x640-6 | ePM1 85% | F9 | 287 | 592 | 640 | 1700 | 125 | C | |

| 0185 287x287x640-6 | ePM1 85% | F9 | 287 | 287 | 640 | 800 | 125 | C | |

| 0185 592x287x640-12 | ePM1 85% | F9 | 592 | 287 | 640 | 1700 | 125 | C | |

| 0185 592x490x640-12 | ePM1 85% | F9 | 592 | 490 | 640 | 2800 | 125 | C | |

| 0185 592x892x640-12 | ePM1 85% | F9 | 592 | 892 | 640 | 5000 | 125 | C | |

| 0185 490x892x640-10 | ePM1 85% | F9 | 490 | 892 | 640 | 4100 | 125 | C | |

| 0185 287x892x640-6 | ePM1 85% | F9 | 287 | 892 | 640 | 2500 | 125 | C | |

| 0185 592x592x520-10 | ePM1 85% | F9 | 592 | 592 | 520 | 3400 | 155 | 1880 | D |

| 0185 490x592x520-8 | ePM1 85% | F9 | 490 | 592 | 520 | 2800 | 155 | D | |

| 0185 287x592x520-5 | ePM1 85% | F9 | 287 | 592 | 520 | 1700 | 155 | D | |

| 0185 287x287x520-5 | ePM1 85% | F9 | 287 | 287 | 520 | 800 | 155 | D | |

| 0185 592x287x520-10 | ePM1 85% | F9 | 592 | 287 | 520 | 1700 | 155 | D | |

| 0185 592x490x520-10 | ePM1 85% | F9 | 592 | 490 | 520 | 2800 | 155 | D | |

| 0185 592x892x520-10 | ePM1 85% | F9 | 592 | 892 | 520 | 5000 | 155 | D | |

| 0185 490x892x520-8 | ePM1 85% | F9 | 490 | 892 | 520 | 4100 | 155 | D | |

| 0185 287x892x520-5 | ePM1 85% | F9 | 287 | 892 | 520 | 2500 | 155 | D | |

| 0185 592x592x370-12 | ePM1 85% | F9 | 592 | 592 | 370 | 3400 | 225 | >2400 | E |

| 0185 490x592x370-10 | ePM1 85% | F9 | 490 | 592 | 370 | 2800 | 225 | E | |

| 0185 287x592x370-6 | ePM1 85% | F9 | 287 | 592 | 370 | 1700 | 225 | E | |

| 0185 287x287x370-6 | ePM1 85% | F9 | 287 | 287 | 370 | 800 | 225 | E | |

| 0185 592x287x370-12 | ePM1 85% | F9 | 592 | 287 | 370 | 1700 | 225 | E | |

| 0185 592x490x370-12 | ePM1 85% | F9 | 592 | 490 | 370 | 2800 | 225 | E | |

| 0185 592x892x370-12 | ePM1 85% | F9 | 592 | 892 | 370 | 5000 | 225 | E | |

| 0185 490x892x370-10 | ePM1 85% | F9 | 490 | 892 | 370 | 4100 | 225 | E | |

| 0185 287x892x370-6 | ePM1 85% | F9 | 287 | 892 | 370 | 2500 | 225 | E |

Camfil launched the Hi-Flo bag filter range in 1969 and it has been our biggest success - Now we are introducing the Next Generation!

Innovation technology and research Commercial and public buildingsA leading steel producer upgraded blower filtration, extending final filter life by 16x, pre-filter life by 4x, and achieving 100% operational availability.

Case studies Energy and Power SystemsGPSC Thailand upgraded the air filters on six of their gas turbines to TurboPulse T12 cartridge filters, achieving $520 000 USD savings annually, 166 000 MMBtu fuel reduction per year, 8 800 tons of CO2 reduction annually, and 3x improved compressor efficiency

Nine questions about Environmental Product Declarations (EPDs). Answered by Anders Sundvik, Vice President of R&D at Camfil.

Sustainability Air quality Standard and regulations Commercial and public buildings

The most important task for a filter is to reduce the amount of particles and pollutants in the ventilation air, but you can also reduce your energy costs if you look at which filters you have in the property by looking at the life cycle cost.

Air quality in meat processing facilities is often the forgotten ingredient within their facility. Did you know that Meat processing factories are susceptible to the spread of airborne viruses and microbes? The temperature and humidity requirements along with the production processes lend to the survival of airborne microbes and viruses. This means that the airborne viruses can survive longer in the air than in other facilities.

Food and beverage Air quality Virus Contamination Control Air cleaners and air purifiers

Air quality has always been an important factor for hotels, whether it has been removing odours from kitchen extracts to ensuring a clean environment by reducing particulate levels.

Air quality Virus Contamination Control Air cleaners and air purifiers Commercial and public buildings

Air quality in your office is important to protecting the health of your employees. Poor air quality can lead to an increased transmission of viruses between employees which can lead to lower productivity and increased sick days in your office

Air quality Virus Contamination Control Air cleaners and air purifiers Commercial and public buildings

Fast food stores are usually located in a crowded commercial area or building where there are problems such as polluted air, gases, and odours. The fresh air fan units in the ventilation system are often close to the pollution source, i.e., exhaust air of other shops in the building.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

Food and beverage Life science and healthcare Standard and regulations

Case Study: Filter Savings At Frozen Food Manufacturer. Three air handling units supplied air to critical processing areas in one of the USA's largest frozen food manufacturing facilities. The pre and final filter combination saved the plant over $33,000 per year.

Dalkia, a leader in the French gas turbine market, launched a national comparative test for various air intake filters, including Camfil's Hi-Flo pre-filters and CamGT EPA filters, to increase power production for their 10 GE LM6000 gas turbines.