Keep your laboratories the safe places they are meant to be. Meet critical safety and reliability requirements and mitigate risk with Camfil’s extensive range of biosafety solutions..

In sensitive environments like pharmaceutical and biopharma facilities with high biosafety levels, both people and the environment risk higher exposure to toxic materials. You need to protect researchers from contamination and prevent microorganisms from coming out of these environments. It could be a matter of life or death.

In the life sciences, pharmaceutical and biopharma facilities have their own special air quality requirements with one thing in common: keeping workers, equipment and processes safe.

Biosafety labs are specialised research labs where scientists study infectious agents, bacteria, viruses, parasites and toxic substances. A few uncollected particles or gas molecules in contaminated air can pose a serious threat out of these labs. It is critical for your air filtration system to contain all of these potentially harmful airborne pathogens.

The necessary protection is defined by four biosafety levels (BSLs). As the BSL increases, there are more requirements and constraints added to the safety precautions that must be followed. The materials observed in highest BSL4 labs can cause severe – or fatal – untreatable diseases in humans.

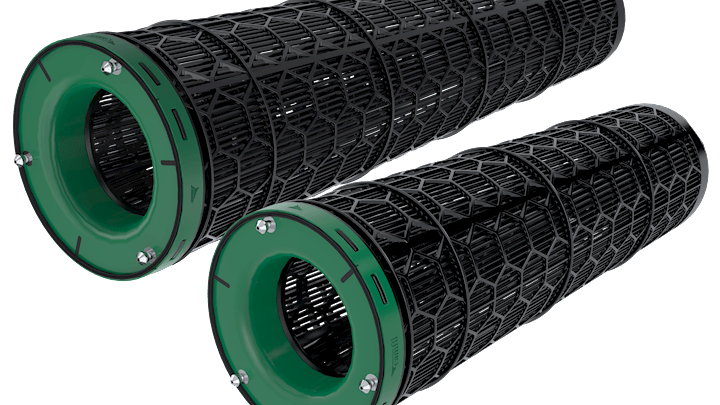

In all cases, filtration of the air both coming in and going out of the lab is crucial. Incoming supply air must be clean to prevent contamination of work that is being conducted. And exhaust air that exits the lab needs to be filtered to keep harmful or deadly substances and organisms from harming people and the outside environment.

Camfil offers dedicated containment solutions to provide even the highest level of safety. Many of the BSL-4 labs around the world currently rely on our containment solutions.

So contact our experts to find out how to reduce the potential spread of disease through the air handling systems of biosafety labs and other pharma facilities. In addition to particle removal efficiency, you’ll also get solutions with a long lifespan, reduced environmental impact and low total cost of ownership.

It's imperative to protect people and the environment from highly dangerous biological, chemical or radioactive risks during research or production operation, especially within defense, the military and university labs.

Controlled environments must protect critical processes and personnel. A high level of air cleanliness is essential to protect products and to contain hazardous compounds. High-quality filtration systems help ensure regulatory compliance and maintain efficient operations.

Protect people, processes, products and equipment while keeping maintenance and energy costs low by keeping air handling units unclogged.

Nowhere are process cleanliness and air quality more critical than in in-vitro fertilisation labs, where studies show a direct relationship between clean air and procedural success.

CamCarb XG Engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageCamfil´s Gold Series dust collector allows French life science company significant savings on energy costs and to safely handle ST1 explosive dust from carding process of alginate fibers.

Life science and healthcare Case studiesOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Air cleaners in the life science industry

HEPA filtration is important to capturing airborne viruses. Learn why HEPA filtration is the preferred solution for capturing viruses in the airstream

Filtration is a physical, biological or chemical operation that separates solid matter – and sometimes fluids – from a mixture with a filter medium that has a complex structure through which only certain elements of the air (or fluid) can pass.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.