The meat processing Industry has been affected by the spread of viruses within its premises. During the Covid 19 outbreak many facilities experienced mass outbreaks that affected their production capabilities as many were forced to shut down for a period of time or reduce operations. We were contacted by Toennies meat processing facility to help find a solution for theses problems

In addition to the general precautions that need to be taken during a pandemic - such as face masks to be worn, social distancing to be observed and work place partitions to be installed - the company wanted to focus on the air quality and how it can help protect their workforce.

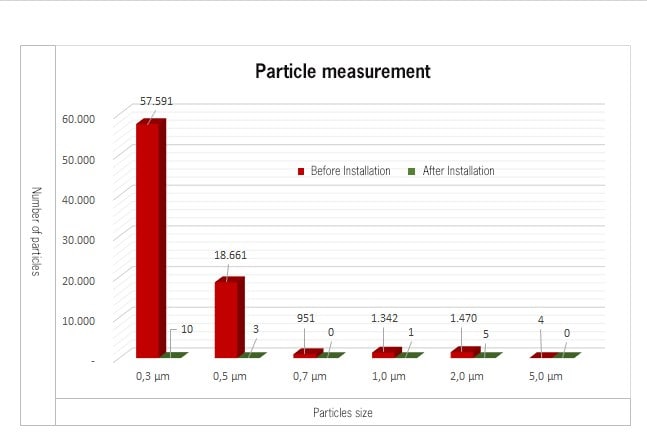

To ensure that the air was cleaned to the required standards (to protect the companies employees), high performance filters needed to be used. High efficiency filters would help capture the airborne viruses and ensure that the HVAC system utilised would have reduced risks.

Meat processing companies require clean air to reduce the particulate levels within the facility to both improve production room conditions and to protect against the spread of airborne viruses. The reason for this is the viruses use airborne particulates to travel and less particulates will reduce this opportunity. As a solution Camfil were able to offer our CC6000 and CC 2000 range of air cleaners that were equipped with H14 HEPA filters.

HEPA filter units used for improving air change rates and reducing particulate levels