One of the world’s Oil & Gas majors had severe problems associated with the operation of their gas turbines. Frequent peaks in inlet air pressure and short filter replacement intervals led to high operational costs. Many of the turbines also suffered from hot corrosion due to poor filtration efficiency. Camfil proposed a solution that not only met their aggressive goal of 8000 hours of filter life, but also delivered higher efficiency and a 50% reduction in pressure drop.

The owner of the turbines, operating several platforms in the Gulf of Thailand, invited the main players in the filtration industry to come up with a solution for upgrading their high velocity filtration systems.

The fleet of gas turbines for mechanical drive, the majority Rolls Royce Avon, Solar Taurus and GE LM2500, were all equipped with high velocity systems and suffering from short filter life, frequent downtime and corrosion issues. After site inspection, Camfil proposed a complete retrofit of the housings and was awarded a filtration system retrofit for one of two neighbouring 16 MW gas turbines.

A high velocity system is normally a static filtration system with droplet separators before and after the filters. High velocity systems have the advantage of reduced size, weight and initial cost. A disadvantage is that there are performance losses due to higher pressure loss through the inlet system. Also, filter efficiencies for small particles are significantly lower than those of a lower velocity system.

The Gulf of Thailand offers a challenging environment with high levels of airborne salt and hot humid winds. In this case, the operator was facing filter replacement intervals every six months and filtration efficiency under 70% on 0.4μm particles (M6 per EN779:2012).

| Climate | Three seasons: cool, hot, rainy |

| Site conditions | High levels of air-borne salts and hot humid winds |

| Average relative humidity | >80% |

| Min. and Max. temp. | 18 - 40 °C/ 68 - 90 °F |

Camfil’s past experience with offshore filtration pointed towards a multiple stage filtration system, but in this application, a mechanical drive engine on a platform, the weight and space restrictions limited the options to a 2-stage system. But would this solution reach the goal of 8000 running hours before filter changeout? The rough environment called for a solution with high resistance to humidity and salt. If salt is ingested in the turbine, the operator faces the risk of irreversible damage to the turbine and extreme costly downtime for engine overhaul. The minimum filtration efficiency grade was set to E12 (EN1822:2009) or 99,5% MPPS to avoid corrosion. Filtration at this level normally has a setback of high pressure loss. The engine interior is kept clean, but it must also work harder to produce the same output due to the higher airflow restriction. To reach the desired reduction in pressure drop, the pre-filtration level was set to F7 with a maximum loss of 110 Pa per filter. To ensure long lifetime and to reduce risk of salt entrainment, the final filter had to have extraordinary dust holding capacity and likewise, offer a low pressure drop. A CamGT 3V-600 final filter with more than 50m² effective media area was the ideal choice for this configuration.

A site survey was conducted by Camfil where necessary data like site conditions, space limitations, and current air flow was gathered. The design process started based on existing information and the outcome of Camfil’s Life Cycle Cost (LCC) analysis. Camfil’s unique software models different parameters such as fouling, pressure drop, engine sensitivity, etc., to select the optimum filter combination.

| ORIGINAL SUPPLY | CAMFIL UPGRADE | |

| Intake system type | High velocity system | Medium velocity system |

| Air flow | 7200 m3/h, filter | 5300 m3/h, filter |

| Pre-filter stage | Bag filter G4 | Cam-Flo XMGT |

| Filnal-filter stage | Bag filter M6 | CamGT 3V-600, E12 |

| Initial pressure drop | 996Pa | 478 Pa |

| Submicron efficiency (at 0.2um - 0.9um) | 15% - 43% | 99.75% - 99.92% |

| Reduction in air resistance | 52% |

The objective for this retrofit job was to get maximum availability, i.e 8000h/year runtime, with only one service stop every 12 months. The end-user also requested increased reliability, as these turbines are powering the export gas compressor.

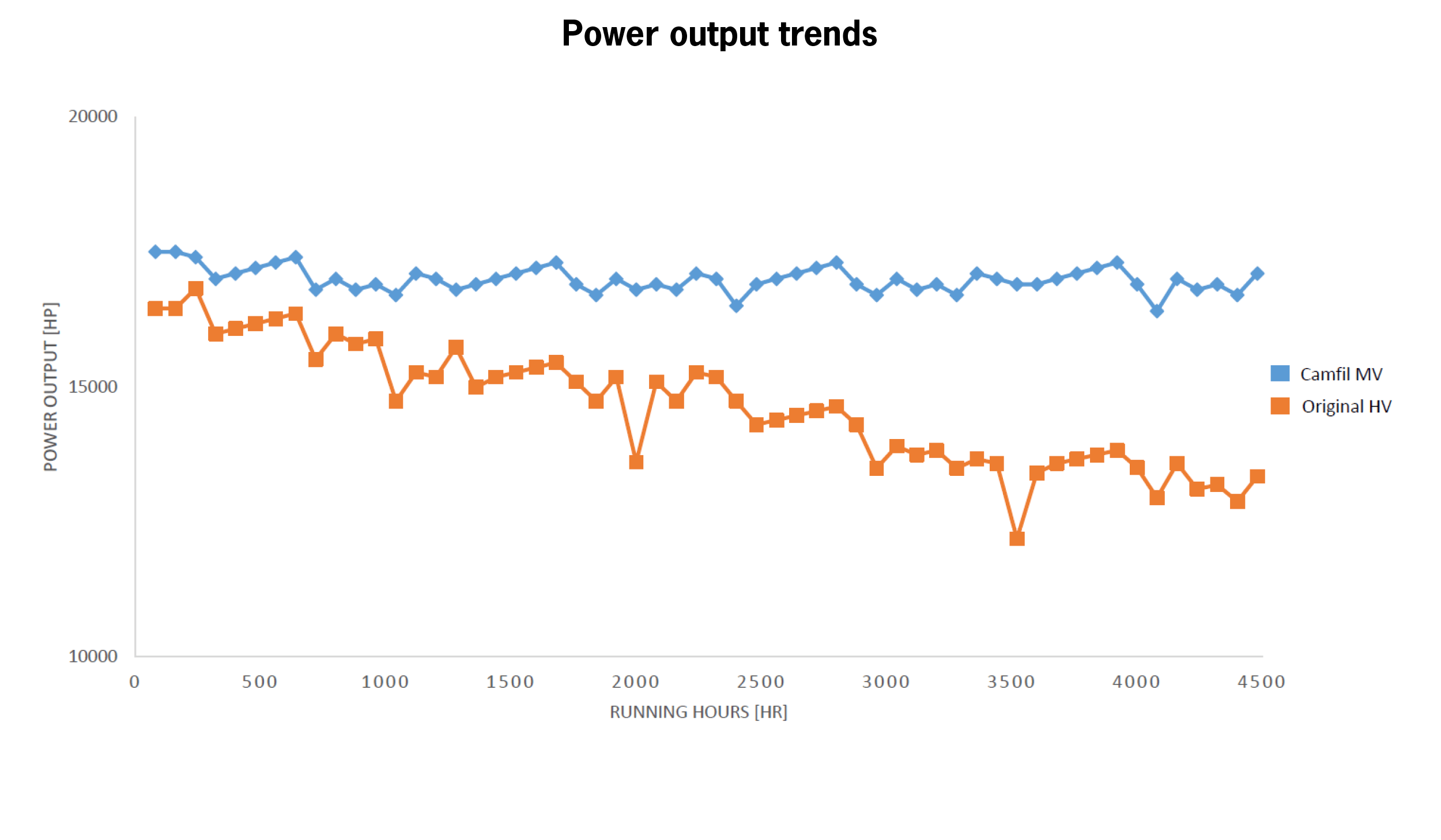

Initial pressure drop was reduced by more than 50% with the new filtration system, from 996 Pa down to 478 Pa. On the first day of installation and after fire up, the upgraded engine gained around 1000 HP, or approximately 6% more, as compared to the higher velocity system.

After six months in operation, the new system showed no increase in pressure drop and no signs of turbine performance degradation. The turbine with the remaining high velocity system suffered from ~25% degradation during the same period, which increased the gap in output even more, compared with the improved and better performing installation.

Cam-Flo XMGT F7 Bag filter with non-discharging synthetic media and high dust holding capacity.

CamGT 3V-600 E12 Barrier type filter with high filtration efficiency and low pressure drop.

|

Train 1, equipped with a medium velocity system and high efficiency deep filters, shows a higher and more stable power output compared to train 2, the high velocity system |