When your industry relies on steady performance, availability and reliability, high quality air filtration is critical to maintain your equipment in top condition for many years. Our air inlet filters and acoustic systems are designed accordingly.

Whether you are on an offshore production platform, a fracking site or a refinery, O&G sites are often challenged with a variety of aggressive contaminants such as salt, heavy hydrocarbons and aggressive gases. On critical processes, these challenges need to be taken care of to maintain top performance of the equipment. Applications can vary from gas turbines, diesel engines, air compressors, generators or ventilation systems for enclosures and control rooms.

Air filtration solutions should be designed according to the operational requirements and local contaminants. Good solutions not only improve performance, they reduce maintenance costs and increase part life. This improves availability, reliability and ultimately, profitability.

Having over 50 years of experience, our solutions are flexible and optimized for each application: from compact EPA solutions offshore, to mobile units on fracking sites, to molecular solutions when subjected to corrosive gas. If you have specific needs, there is a good chance we have industry experience to help you. With test rigs that mimic extreme conditions, from salt & water spray to high air flows and high burst pressure, our R&D group is focused on ensuring reliability. We challenge our products in real site conditions using our mobile testing trailers, the CamLabs, and are always ready to show you actual performance data.

Our patented solutions like the CamGT 3V-600 have pushed the industry limits when it comes to water handling capability, salt removal efficiency and lower operating pressure drop. When reliability is critical, your air filters should be just as dependable. We strive to understand air and local conditions better than anyone else. A little obsessive? Maybe. But, when up to 98% of what goes into your equipment is air, we believe it’s a good thing. By providing the facts you need to empower your decisions, you can optimize output and efficiency. As the most predictable air solutions provider, Camfil keeps your equipment working better and longer, while removing the element of surprise. We help you stay in control. If you are designing a new system or simply looking to improve your current performance, ask us about our life cycle cost software, our air sampling solutions or for a CamLab test.

No shelter is complete, or completely safe, without the proper air filtration system. Prevent fallout or airborne agents from infiltrating the air you breathe in these safe havens with a quality air filtration system.

Protect the membranes that clean your biogas before injection. Control corrosion and abrasion with adsorbents in leak-free housings. Efficiently and safely remove hydrogen sulfide (H2S) and siloxanes to help eliminate unscheduled repairs and downtime.

Many industries rely on electronic and electrical control equipment for safe and efficient operation. To avoid unscheduled breakdowns, the equipment must be protected from corrosion originating from chemicals used in their manufacturing processes.

Alto Garda Power upgraded their filtration to a 2-stage static system for their LM6000 gas turbine. The benefits included a 50% reduction of pressure drop, 4x final filter lifetime, 9x prefilter lifetime, and more.

Energy and Power Systems Case studies

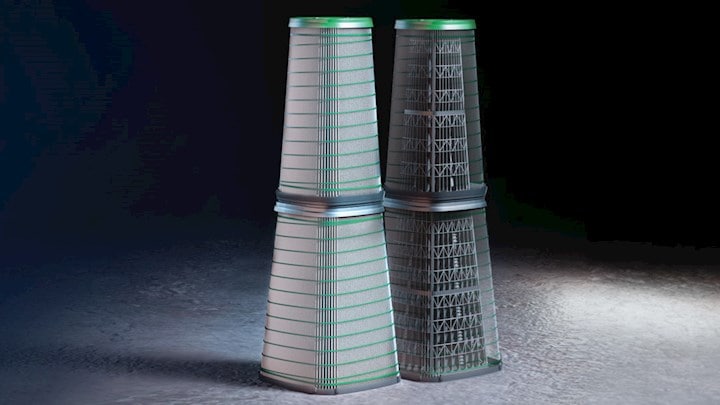

The newest pulse technology for the 21st century, TurboPulse takes a modern approach to filter design with many new features engineered to improve filter life and pulse performance for turbomachinery.

Energy and Power SystemsCamCleaner Ventilation System Lower the Spread of Airborne Infections at PTT Gas

Not all people who purchase our products are experts in air filtration and they shouldn’t have to be either. The purpose of Camfil City is to give everyone a chance to learn the basics of what our clean air solutions can do for them.

For the first time, there is a GT-specific filter efficiency standard. Discover how ISO29461-1 can help you select the right filters for any turbomachinery application.

CamCarb VG modules with loose-fill media are robust solutions suited for make-up air (outdoor air) and recirculation air systems. The primary use is the control of acidic gases that are responsible for the corrosion of electronics and electrical equipment in heavy process industries such as pulp and paper mills, petrochemical refineries, mining and metal refining operations, and wastewater treatment plants.

Corrosion of electronic process control equipment can cause disruptions in production leading to lower productivity and lower profitability - this can be expensive to fix.

Camfil Power Systems (PS) provides filtration and acoustical solutions for turbomachinery including gas turbines, generators,industrial air compressors and diesel engines. Turbomachinery technology has evolved tremendously over the past decades.

Case Study: Protecting Family-Owned Auto Body Shop. With a reputation as the best in their area, the third generation, family-owned body shop rehabilitates the exterior of foreign and domestic vehicles as well as motorcycles, specialising in classic and specialty cars.