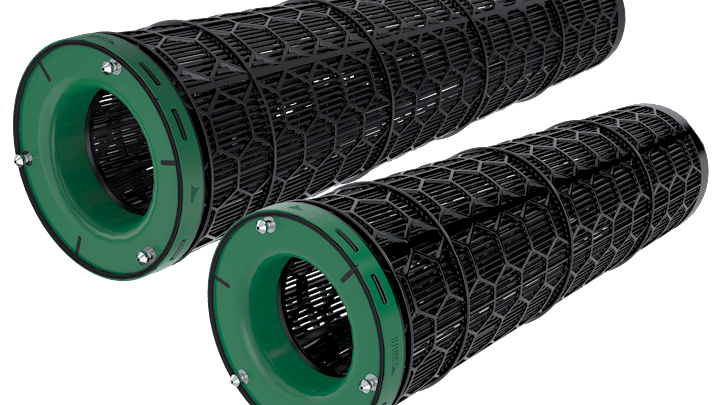

A metal cylindrical molecular filter filled with Camfil activated alumina or activated carbon.Typically installed in supply, recirculation, and exhaust air systems in commercial, industrial, and process applications with temperatures up to 80ºC. Their refillable design provides a low total cost of ownership for the removal of odorous and irritant gases.

| Item Type | Airflow (m3/h) | Diameter 1 (mm) | Length 1, Cylindrical (mm) | Pressure drop Initial (Pa) | Nominal weight (kg) | Nominal weight (lbs) | Optimum RH (%) | Optimum temperature (°C) | Optimum temperature (°F) |

|---|---|---|---|---|---|---|---|---|---|

| CamCarb CM 2600 VOC | 2500 | 145 | 450 | 110 | 3.9 | 8.6 | 0-70 | Max. 40 | Max.104 |

| CamCarb CM 2600 H2S_Mercaptans | 2500 | 145 | 450 | 110 | 3.9 | 8.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CM 2600 Acids | 2500 | 145 | 450 | 110 | 3.9 | 8.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CM 2600 Bases | 2500 | 145 | 450 | 110 | 3.9 | 8.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CM 3500 VOC | 3400 | 145 | 600 | 190 | 5.2 | 11.5 | 0-70 | Max. 40 | Max.104 |

| CamCarb CM 3500 H2S_Mercaptans | 3400 | 145 | 600 | 190 | 5.2 | 11.5 | 40-60 | 10-60 | 50-140 |

| CamCarb CM 3500 Acids | 3400 | 145 | 600 | 190 | 5.2 | 11.5 | 40-90 | 10-60 | 50-140 |

| CamCarb CM 3500 Bases | 3400 | 145 | 600 | 190 | 5.2 | 11.5 | 40-90 | 10-60 | 50-140 |

CamCarb XG Engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverage

Restaurants have odours coming from a variety of sources and they all have one thing in common, they spread 'air pollution'. Odours are one of the leading causes of air pollution at restaurants or food courts and the odour profile from a kitchen depends on various factors.

Air quality Commercial and public buildings Food and beverageFood odours are often a problem for commercial kitchens and industrial food producers when they are located near residential dwellings. Learn how these odours can be controlled using molecular filtration

S.Silpa Co., Ltd., Thailand faced constant odor nuisance and high VOC levels in their factory. This is due to the usage of various chemicals in the printing process that generate volatile organic compounds (VOCs) when exposed to heat, such as thinner solutions, alcohols, inks, cleaning solvents, vinyl sheets.

Awareness and regulations in the life science and pharmaceutical processes are essential as critical molecules in the mistaken place can cause failure of the production process which can be extremely harsh to the outcome. In the pharmaceutical and life science industries, clean rooms and laboratories are often used for various purposes. These cleanrooms are subject to a high level of cleanliness of numerous particles and molecules

Aftermath of flooding driver government office to turn to CamCleaner vertical air cleaners for eliminating mold odor