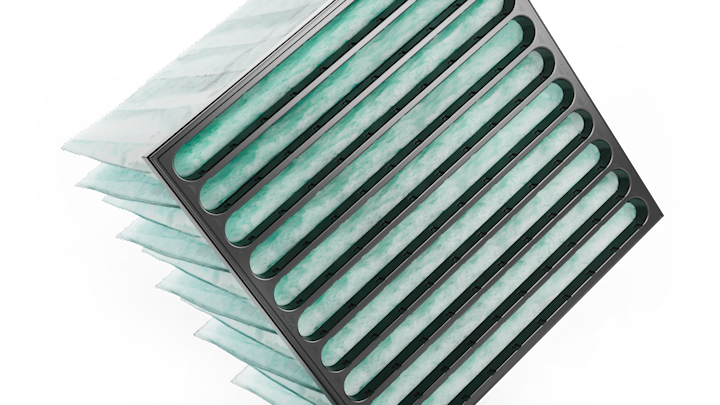

The premium range of glass fiber bag filters with steel frame. These filters have the highest energy efficiency and longest operating life. With their low pressure drops and high dust holding capacites, lowest labour cost thanks to less frequent filter changes can be achieved. Available in all efficiencies according to ISO16890.

| Item Type | ISO/PM rating | Filter Class EN779 | Width (mm) | Height (mm) | Depth (mm) | Airflow (m3/h) | Pressure drop Initial (Pa) | Energy (kWh/year) | Energy Class (Eurovent) | Pockets (no.) |

|---|---|---|---|---|---|---|---|---|---|---|

| M6 | ePM2,5 50% | M6 | 592 | 592 | 640 | 3400 | 55 | 748 | A | 12 |

| N6 | ePM2,5 50% | M6 | 490 | 592 | 640 | 2800 | 55 | A | 10 | |

| O6 | ePM2,5 50% | M6 | 287 | 592 | 640 | 1700 | 55 | A | 6 | |

| P6 | ePM2,5 50% | M6 | 592 | 592 | 520 | 3400 | 65 | 992 | C | 10 |

| Q6 | ePM2,5 50% | M6 | 490 | 592 | 520 | 2800 | 65 | C | 8 | |

| R6 | ePM2,5 50% | M6 | 287 | 592 | 520 | 1700 | 65 | C | 5 | |

| TM6 | ePM2,5 50% | M6 | 592 | 592 | 370 | 3400 | 70 | 1280 | C | 12 |

| TN6 | ePM2,5 50% | M6 | 490 | 592 | 370 | 2800 | 70 | C | 10 | |

| TO6 | ePM2,5 50% | M6 | 287 | 592 | 370 | 1700 | 70 | C | 6 | |

| M7 | ePM1 60% | F7 | 592 | 592 | 640 | 3400 | 65 | 803 | A+ | 12 |

| N7 | ePM1 60% | F7 | 490 | 592 | 640 | 2800 | 65 | A+ | 10 | |

| O7 | ePM1 60% | F7 | 287 | 592 | 640 | 1700 | 65 | A+ | 6 | |

| P7 | ePM1 60% | F7 | 592 | 592 | 520 | 3400 | 75 | 943 | A | 10 |

| Q7 | ePM1 60% | F7 | 490 | 592 | 520 | 2800 | 75 | A | 8 | |

| R7 | ePM1 60% | F7 | 287 | 592 | 520 | 1700 | 75 | A | 5 | |

| TM7 | ePM1 60% | F7 | 592 | 592 | 370 | 3400 | 95 | 1275 | C | 12 |

| TN7 | ePM1 60% | F7 | 490 | 592 | 370 | 2800 | 95 | C | 10 | |

| TO7 | ePM1 60% | F7 | 287 | 592 | 370 | 1700 | 95 | C | 6 | |

| M8 | ePM1 70% | F8 | 592 | 592 | 640 | 3400 | 130 | 12 | ||

| N8 | ePM1 70% | F8 | 490 | 592 | 640 | 2800 | 130 | 10 | ||

| O8 | ePM1 70% | F8 | 287 | 592 | 640 | 1700 | 130 | 6 | ||

| P8 | ePM1 70% | F8 | 592 | 592 | 520 | 3400 | 160 | 10 | ||

| Q8 | ePM1 70% | F8 | 490 | 592 | 520 | 2800 | 160 | 8 | ||

| R8 | ePM1 70% | F8 | 287 | 592 | 520 | 1700 | 160 | 5 | ||

| TM8 | ePM1 70% | F8 | 592 | 592 | 370 | 3400 | 205 | 12 | ||

| TN8 | ePM1 70% | F8 | 490 | 592 | 370 | 2800 | 205 | 10 | ||

| TO8 | ePM1 70% | F8 | 287 | 592 | 370 | 1700 | 205 | 6 | ||

| M9 | ePM1 85% | F9 | 592 | 592 | 640 | 3400 | 125 | 1520 | C | 12 |

| N9 | ePM1 85% | F9 | 490 | 592 | 640 | 2800 | 125 | C | 10 | |

| O9 | ePM1 85% | F9 | 287 | 592 | 640 | 1700 | 125 | C | 6 | |

| P9 | ePM1 85% | F9 | 592 | 592 | 520 | 3400 | 155 | 1880 | D | 10 |

| Q9 | ePM1 85% | F9 | 490 | 592 | 520 | 2800 | 155 | D | 8 | |

| R9 | ePM1 85% | F9 | 287 | 592 | 520 | 1700 | 155 | D | 5 |

Camfil launched the Hi-Flo bag filter range in 1969 and it has been our biggest success - Now we are introducing the Next Generation!

Innovation technology and research Commercial and public buildingsGPSC Thailand upgraded the air filters on six of their gas turbines to TurboPulse T12 cartridge filters, achieving $520 000 USD savings annually, 166 000 MMBtu fuel reduction per year, 8 800 tons of CO2 reduction annually, and 3x improved compressor efficiency

Energy and Power Systems Case studiesNine questions about Environmental Product Declarations (EPDs). Answered by Anders Sundvik, Vice President of R&D at Camfil.

Sustainability Air quality Standard and regulations Commercial and public buildings

A leading steel producer upgraded blower filtration, extending final filter life by 16x, pre-filter life by 4x, and achieving 100% operational availability.

Using Camfil Life Cycle Cost (LCC) Analysis software, Camfil experts can conduct a comparative analysis of different air filters to provide a comprehensive report on potential savings.

Sustainability Take a Breath Air quality Commercial and public buildings

Why is ventilation so important, how does it work and what factors ensure a healthy and productive indoor air environment in our buildings?

How do you best protect yourself from air pollution in a city environment? Is it safe to open a window to let the breeze in to cool your premises on a warm day? What about pollutants already present in your indoor air?

Air quality Air cleaners and air purifiers Commercial and public buildings

The air in our buildings is often 2-5 times more polluted, and in some cases, even a hundred times more polluted than the air outside. So, where do the pollutants in the indoor air come from and how do we mitigate their impact?

Air quality Air cleaners and air purifiers Commercial and public buildings

What are some of the challenges moving forward to achieve healthy and energy-efficient indoor air environments? And what are some of the new air filtration solutions that could potentially become a reality in the years to come?

Sustainability Air quality Innovation technology and research Commercial and public buildings

A recent United Nations study shows that many countries lack the necessary laws and regulations to combat air pollution. There are also significant differences in how countries monitor and measure air quality and present their data.

Air quality Standard and regulations Commercial and public buildings

What does poor air quality in schools do to a child’s health, well-being and ability to learn? Why are children more vulnerable to air pollution than adults? And how can you achieve, or advocate for, a healthy indoor air environment in the classroom?

Air quality Air cleaners and air purifiers Commercial and public buildings

Camfil is an official sponsor of the Swedish pavilion by providing advanced clean air solutions that ensure better indoor air quality for visitors. EXPO 2020 in Dubai has started on October 1st, 2021 and will conclude on March 31st, 2022.

Sustainability Take a Breath Air quality Education and experience Innovation technology and research

In cold winter months, our energy and heat needs increase as the temperature drops outside. The sudden temperature change can lead to a sharp increase in pollution levels in the outdoor air. In addition, the cold itself means that we spend even more time indoors, which brings us closer to each other. Many don't understand how it affects us and our indoor environment.

Air quality Air cleaners and air purifiers Commercial and public buildings

Camfil is in the vanguard of a growing international movement to reduce the negative health effects of polluted air. As a leader in clean air solutions, we actively inform and educate customers, decision-makers, and the general public about threatening air pollutants and the tangible benefits of effective air filtration and high indoor air quality.

Take a Breath Air quality Virus Contamination Control Air cleaners and air purifiers Commercial and public buildings

Hi-Flo bag air filters and CamGT EPA air filter upgrade reduces compressor efficiency degradation by 80%, slashes 3 offline filter replacements, 7 online pre-filter replacements, and 3 offline water washes per year.

Air quality in meat processing facilities is often the forgotten ingredient within their facility. Did you know that Meat processing factories are susceptible to the spread of airborne viruses and microbes? The temperature and humidity requirements along with the production processes lend to the survival of airborne microbes and viruses. This means that the airborne viruses can survive longer in the air than in other facilities.

Food and beverage Air quality Virus Contamination Control Air cleaners and air purifiers

Air quality in your office is important to protecting the health of your employees. Poor air quality can lead to an increased transmission of viruses between employees which can lead to lower productivity and increased sick days in your office

Air quality Virus Contamination Control Air cleaners and air purifiers Commercial and public buildings

Air quality has always been an important factor for hotels, whether it has been removing odours from kitchen extracts to ensuring a clean environment by reducing particulate levels.

Air quality Virus Contamination Control Air cleaners and air purifiers Commercial and public buildings

Restaurants have odours coming from a variety of sources and they all have one thing in common, they spread 'air pollution'. Odours are one of the leading causes of air pollution at restaurants or food courts and the odour profile from a kitchen depends on various factors.

Food and beverage Air quality Commercial and public buildings

Fast food stores are usually located in a crowded commercial area or building where there are problems such as polluted air, gases, and odours. The fresh air fan units in the ventilation system are often close to the pollution source, i.e., exhaust air of other shops in the building.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

Food and beverage Life science and healthcare Standard and regulations

Dalkia, a leader in the French gas turbine market, launched a national comparative test for various air intake filters, including Camfil's Hi-Flo pre-filters and CamGT EPA filters, to increase power production for their 10 GE LM6000 gas turbines.

Case Study: Filter Savings At Frozen Food Manufacturer. Three air handling units supplied air to critical processing areas in one of the USA's largest frozen food manufacturing facilities. The pre and final filter combination saved the plant over $33,000 per year.