A cylindrical, corrosion-resistant molecular filter filled with Camfil activated alumina or activated carbon. They are the most versatile gas-phase air filter installed in supply, recirculation, and exhaust air systems in commercial, industrial, and process applications. The design provides the best total cost of ownership for the removal of corrosive, odorous, and irritant gases.

| Item Type | Airflow (m3/h) | Diameter 1 (mm) | Length 1, Cylindrical (mm) | Pressure drop Initial (Pa) | Nominal weight (kg) | Nominal weight (lbs) | Optimum RH (%) | Optimum temperature (°C) | Optimum temperature (°F) |

|---|---|---|---|---|---|---|---|---|---|

| CamCarb CG 1300 SO2_H2S^³ | 1250 | 148 | 240 | 80 | 2.4 | 5.3 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 1300 Acids_H2S^³ | 1250 | 148 | 240 | 80 | 2.4 | 5.3 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 1300 VOC | 1250 | 148 | 240 | 80 | 1.6 | 3.6 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 1300 H2S_Mercaptans | 1250 | 148 | 240 | 80 | 1.6 | 3.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 1300 Acids | 1250 | 148 | 240 | 80 | 1.6 | 3.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 1300 VOC_O3_Acid_H2S | 1250 | 148 | 240 | 100 | 2.0 | 4.4 | 40-70 | 10-40 | 50-104 |

| CamCarb CG 1300 VOC_O3_NO2_SO2 | 1250 | 148 | 240 | 60 | 1.5 | 3.3 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 1300 Bases | 1250 | 148 | 240 | 80 | 1.6 | 3.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 2600 SO2_H2S^³ | 2500 | 148 | 452 | 135 | 4.4 | 9.7 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 2600 Acids_H2S^³ | 2500 | 148 | 452 | 135 | 4.4 | 9.7 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 2600 VOC | 2500 | 148 | 452 | 135 | 2.9 | 6.4 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 2600 H2S_Mercaptans | 2500 | 148 | 452 | 135 | 2.9 | 6.4 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 2600 Acids | 2500 | 148 | 452 | 135 | 2.9 | 6.4 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 2600 VOC_O3_Acid_H2S | 2500 | 148 | 452 | 150 | 3.6 | 7.9 | 40-70 | 10-40 | 50-104 |

| CamCarb CG 2600 VOC_O3_NO2_SO2 | 2500 | 148 | 452 | 100 | 2.8 | 6.2 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 2600 Bases | 2500 | 148 | 452 | 135 | 2.9 | 6.4 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 3500 SO2_H2S^³ | 3400 | 148 | 595 | 175 | 5.7 | 12.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 3500 Acids_H2S^³ | 3400 | 148 | 595 | 175 | 5.7 | 12.6 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 3500 VOC | 3400 | 148 | 595 | 175 | 3.8 | 8.4 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 3500 H2S_Mercaptans | 3400 | 148 | 595 | 175 | 3.8 | 8.4 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 3500 Acids | 3400 | 148 | 595 | 175 | 3.8 | 8.4 | 40-90 | 10-60 | 50-140 |

| CamCarb CG 3500 VOC_O3_Acid_H2S | 3400 | 148 | 595 | 210 | 4.7 | 10.4 | 40-70 | 10-40 | 50-104 |

| CamCarb CG 3500 VOC_O3_NO2_SO2 | 3400 | 148 | 595 | 165 | 3.7 | 8.2 | 0-70 | Max. 40 | Max.104 |

| CamCarb CG 3500 Bases | 3400 | 148 | 595 | 175 | 3.8 | 8.4 | 40-90 | 10-60 | 50-140 |

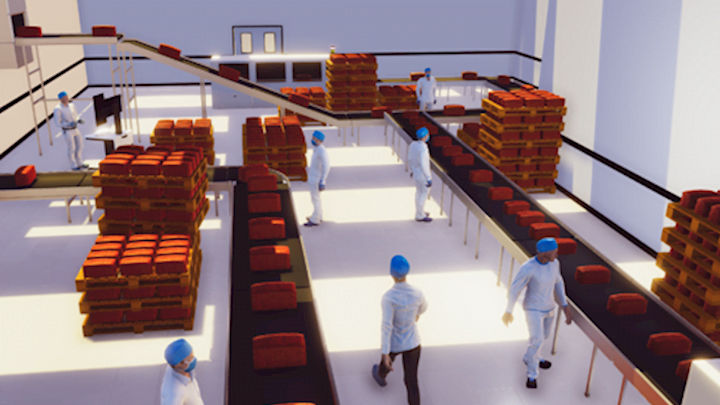

In the manufacturing industry air quality can be compromised by the production processes.

Air cleaners and air purifiers Manufacturing and machinery

Find out how Camfil solutions can help you protect your patients and staff in your hospital

Air cleaners and air purifiers Life science and healthcareAftermath of flooding driver government office to turn to CamCleaner vertical air cleaners for eliminating mold odor

If you are looking to expand your knowledge on the impact of air filtration on your gas turbines and other turbomachinery, look no more!