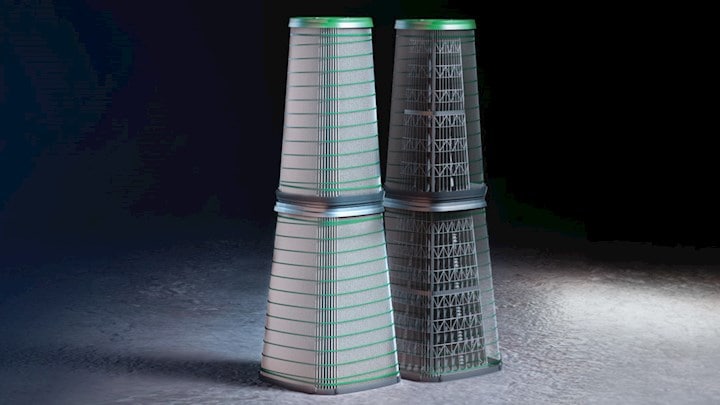

The GTC HemiPleat has an excellent self cleaning filter design that makes it a good pulse filter for gas turbines. Its non-discharging and synthetic media offers the ideal balance between pressure drop, filtration efficiency, and service life. The GTC air filtration cartridges are suitable for high humidity applications, such as coastal/tropical.

The newest pulse technology for the 21st century, TurboPulse takes a modern approach to filter design with many new features engineered to improve filter life and pulse performance for turbomachinery.

Energy and Power Systems

The Watson Cogeneration Plant operates 4 GE, Frame 7EA engines and produces 400 MW for local refineries and sells excess electricity to the grid. The Plant Manager requested air intake efficiency, pressure drop, and water tests from Camfil. The test results revealed the true impact of the synthetic cartridge filters on gas turbine performance.

Case studies Energy and Power SystemsA side by side comparison shows the benefits of higher grade GTC F9 gas turbine air intake filters for two RB211 gas turbines, even in very clean rural areas. It means a cleaner engine, higher power output, fewer water washes, and fuel savings.