Working in the food and beverage industry, you are aware that without effective filtration, food, beverages and processes can become contaminated due to poor air quality. We’d like to share our knowledge to educate and inspire you to optimise your food and beverage company to meet the strict regulatory industry requirements.

Companies in the food and beverage industry have a responsibility to ensure the safety of all people, products and processes. Food and beverage contamination grabs people’s attention because eating and drinking are vital and necessary parts of everyone’s day.

Did you know Camfil have a full range of retrofit filters that can be utilised in all the most common brands on the market. Camfil filters are not just designed to work but to optimise your dust extraction systems performance

Manufacturing and machinery Energy and Power Systems Food and beverage Life science and healthcare

CamCarb XG Engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageIn the realm of controlled environments, where precision, purity, and protection are paramount, High-Efficiency Particulate Air (HEPA) filters emerge as unsung heroes

Camfil provides fully tailored turnkey solutions for exhaust air applications that meet the specific demands of your processes and local regulatory requirements. From a single unit to a complete plant-wide system, including dust, fume and mist extraction as well as molecular filtration.

Learn more on how Camfil´s GoldLink Connect remote monitoring system helped a metalworking company to significantly reduce power consumption and compressed air consumption on their dust collectors.

This case study highlights the safe handling of combustible food dust with ATEX regulation compliance and increased savings.

Processes in manufacturing facilities often generate dust and fumes which for example can pose health risks for your operators or compromise the quality and safety of your products. Determining the right capture and filtration solution helps to protect against the main risks of uncontrolled emissions and thus to create safe work environments.

Manufacturing, processing and packing of food and beverage products and their ingredients usually generates dust. This, in turn, can create a number of significant challenges for the industry. When dust particles become airborne they can threaten employee health, contaminate products and/or cause combustible dust incidents. Using a high-efficiency dust collection system helps to reduce those risks and keep your facility in compliance with local HSE regulations.

When purchasing dust collection systems and filter cartridges, the initial purchase price is just the tip of the iceberg. The true costs – energy, consumables and operations – are lurking below the surface. The good news is that there are ways to reduce these costs over the long term.

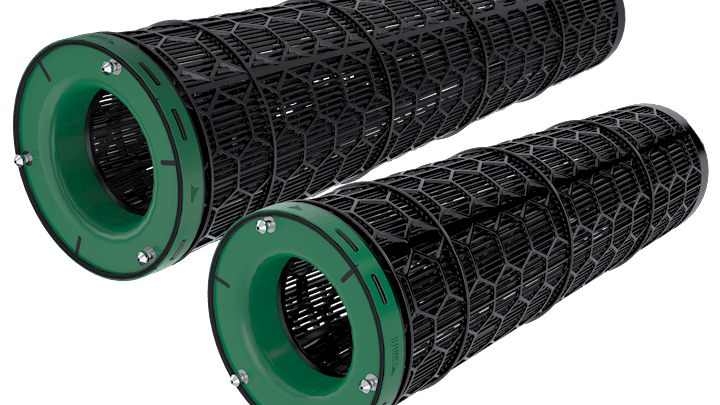

HemiPleat is, in short, the uniquely, patented media pleating technology Camfil use to create highly efficient filter cartridges that outlast and outperform competitors alternatives.

Dust collection systems are an important part of any manufacturing process, so they need to be sized and designed properly. One critical design component is specifying the proper filtration media, which requires analysis of the dust in the process and all operating conditions.

Dust collection systems are all safety devices and thus state-of-the art modern methods of validation and certification are required. Furthermore it is vital to ensure that the system is still in compliance after perhaps changed process conditions, to provide maximum safety for personnel and the facility. It is also recommended to carry out quality audits, process reliability surveys and annual safety inspections.

Almost all industrial manufacturing, processing or packaging applications generate dust as a side effect. Many of these dusts are both combustible as well as explosive, and removing them from the work place can significantly reduce the risk of serious accidents. It is estimated that there are approximately 2,000 dust explosions in Europe annually. Most of these are minor but some are very destructive. So by extracting the dust, the risk in the production is reduced, but unless the extraction system is safe the risk is just moved.

CINCAPORC had concerns regarding the Porcine reproductive and respiratory syndrome (PRRS) outbreak, together with the engineering PRODES in the livestock farm. To study the case and the possible solution, they visited‚ ‘The Grandmother Farms‘ in Minnesota, USA that is using Camfil‘s air filtration solutions.

Not all people who purchase our products are experts in air filtration and they shouldn’t have to be either. The purpose of Camfil City is to give everyone a chance to learn the basics of what our clean air solutions can do for them.

A properly designed and installed dust collection system will effectively catch, convey and separate hazardous and nuisance dusts. Our new ePoster pinpoints key areas to watch and signs to look for that will help you avoid problems with your dust collection system and to keep up process availability in your production facility.

Dust collectors are necessary safety systems in many manufacturing and processing plants, thus as in the food processing industry. But if they are not designed, installed and maintained properly, these systems themselves can cause serious problems. In this eBook we highlight 10 ways how to make sure your dust collection system is up to the tasks of keeping workers safe, maximising production uptime and meeting regulatory compliance.

Handling dust produced due to sugar can be challenging as it is explosive, sticky and abrasive. In this facility, the customer produces soft gummy sweet sugar coated candy and required an efficient and reliable dust extraction solution for a new packaging line.

The new Absolute V HEPA range of air filters is all about making your life simpler, safer and more eco friendly. This is achieved by offering you filters that are extremely light-weight, robust and easy to handle. Filters that provide world-leading protection for your operations.

Dealing with airborne odours, toxins and gases can be a big challenge. Learn about how Molecular Contamination Control and how it can protect against the harmful effects of these airborne contaminants.

Food2Train's goal is to ensure an optimal hygienic profile of its products and a consequent increase in shelf-life. With this motive, since the start of the plant, Food2Train is working on a concept of cleanroom based environment in the food production cycle. This environment is dedicated to the portioning and distribution of its products hygienically along with eliminating the number of airborne microorganisms from the process to ensure maximum protection of the product.

The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Case Study: Dual 9 air filter. Higher performance, extended life (3-4 times longer), lower total cost and increased containment collection.

Air is a vital ingredient in food and beverage production. Protecting your production process and final product has never been easier

Air quality in meat processing facilities is often the forgotten ingredient within their facility. Did you know that Meat processing factories are susceptible to the spread of airborne viruses and microbes? The temperature and humidity requirements along with the production processes lend to the survival of airborne microbes and viruses. This means that the airborne viruses can survive longer in the air than in other facilities.

Every business depends on its surrounding environment and understanding the needs truly depends on identifying the problems. One fact that will remain unchanged even after the COVID-19 pandemic storm settles is that 'air travels'. It is important to highlight the potential risks surrounding the business such as air pollution.

In the meat processing industry, there is a big focus on ventilation technology for the prevention of the virus outbreak. Due to a lack of standards in the industry around ventilation, there is very little guidance around what should be considered as the clean air requirements for the facility.

Restaurants have odours coming from a variety of sources and they all have one thing in common, they spread 'air pollution'. Odours are one of the leading causes of air pollution at restaurants or food courts and the odour profile from a kitchen depends on various factors.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

Most people understand air pollution and poor air quality are issues that are important, but it often remains an abstract concept until it affects them directly. But food and beverage contamination grabs people's attention.