For over a decade, Camfil and gas turbine OEMs have worked together to design optimum solutions for offshore, coastal, and harsh environment applications. An OEM major approached Camfil with the need for a high efficiency compact solution. The idea was to have a product with a footprint identical to the existing high velocity filter houses while ensuring longer filter replacement intervals, lower initial pressure drop (dP), greater hydrophobicity characteristics, and EPA efficiency for particulate removal (especially salt).

Foxtrot International, an upstream oil and gas player, manages a gas exporting platform situated offshore Ivory Coast, Africa, where they operate two mechanical drive gas turbine units (5MW each) that drive compressors with high availability requirements.

Units A and B are exposed to harsh environmental conditions that led to spikes in dP, and excessive engine degradation from fouling and corrosion. Consequently, Foxtrot was forced to schedule unwanted shutdowns for maintenance.

The offshore platform is subjected to high humidity and temperatures, sea salt in the air, along with other contaminants from the flare, supply vessels, process equipment, and contaminants from lube oil exhaust ventilation.

In addition, the site is exposed to extreme dust as a result of Harmattan sandstorms that occur four months of the year between late November to mid-March. During this dry season, dust travels from the Sahara to the Ivory Coast and is transported hundreds of kilometers across the Atlantic Ocean onto the platform1.

Although the systems are located between decks and are not exposed to direct rain or sea spray, the units, particularly Unit B, often challenged with saltwater and Harmattan storms.

The original intake system was a high velocity (31,298 CFM) configuration with nine M6 efficiency final filters (3W x 3H) per turbine.

Due to the extreme site conditions, Unit B's turbine performance significantly decreased.

Camfil sent technical site representatives to evaluate the existing air inlet systems and their surroundings. Due to Camfil’s track record of successful offshore filtration systems, the OEM awarded Camfil with the project.

Foxtrot’s objectives were to eliminate degradation and minimize maintenance requirements to once per year. To achieve this, Camfil recommended redesigning the filter house to the Compact EPA Filter solution consisting of:

The new filter house uses nine prefilters back to back with nine high efficiency filters to fit in the existing footprint.

To minimize downtime during the installation process, coordination effort was key. The Camfil team went onsite to supervise the installation work and on-the-spot troubleshooting. They assessed the equipment required and the manpower needed.

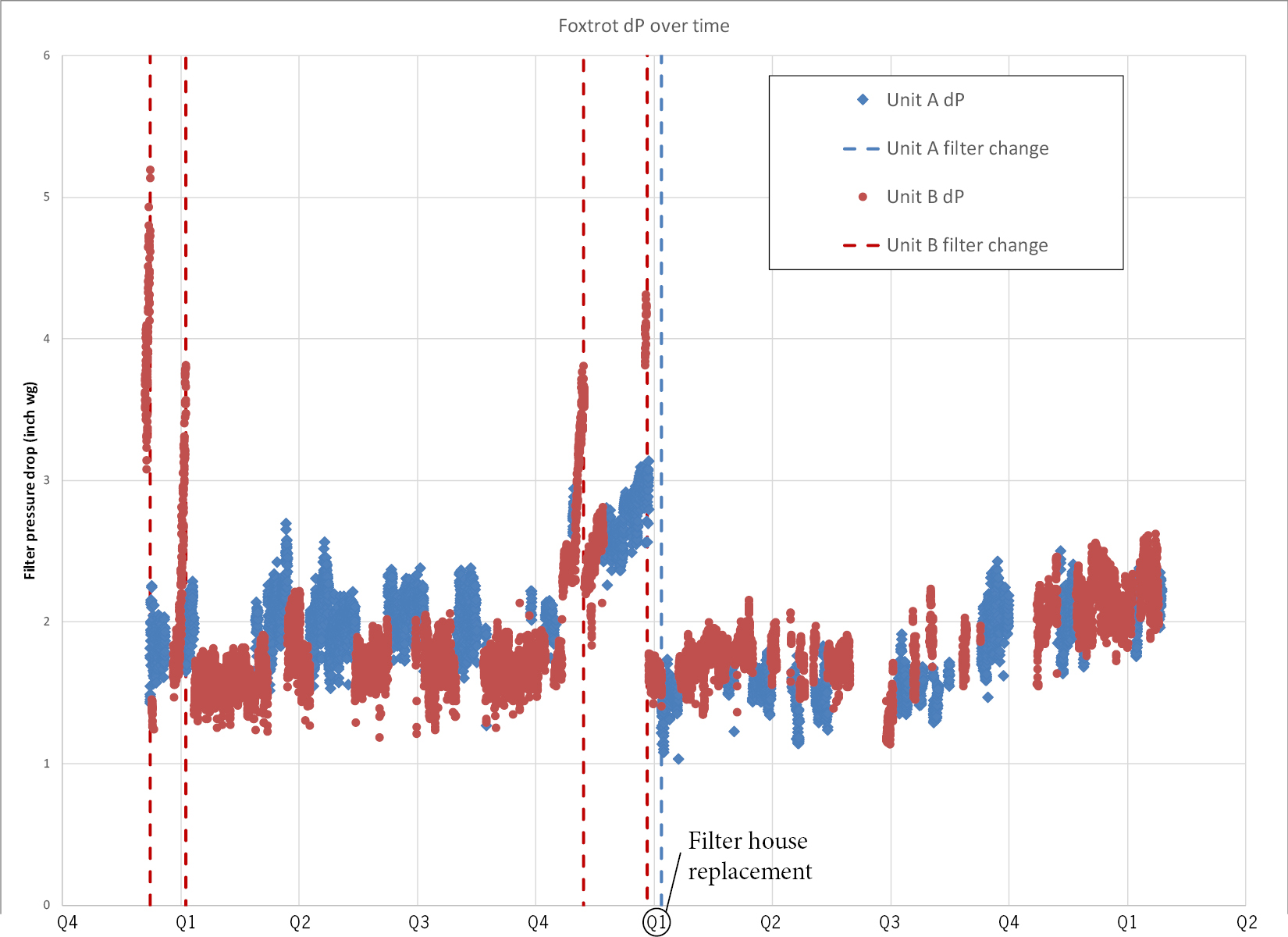

Figure 1 shows dP over time for both engines.

Engine B is situated in a more challenging area on the platform, resulting in multiple dP spikes pre-upgrade, sometimes exceeding 5.2” w.g. At each peak, an unplanned shutdown was required for filter replacement.

Once Foxtrot upgraded to the Compact EPA Static solution in March 2016, dP stabilized and the filters lasted the full year without any unscheduled shutdowns.

Engine A is in a cleaner area on the platform, resulting in a more stable dP and fewer spikes, pre- and post-upgrade. Despite its cleaner conditions, dP spiked to 3.1" w.g. pre-upgrade, whereas dP had not exceeded 1.7" w.g. with the Compact EPA solution.

The results are impressive since the upgraded solution delivers lower dP while offering EPA efficiency versus the original M6 efficiency. A typical E10 EPA filter solution is expected to have a higher dP than an M6 filter solution when using the same housing size. The Compact Static EPA filter solution is able to deliver an EPA efficiency performance at a lower dP and with a longer service life, resulting in safer, more reliable, and more productive operations.

The site manager further confirmed a significant improvement in engine performance, allowing them to run a full year without any unwanted shutdowns that were previously caused by fouling and corrosion with the original system.

Compared to the original M6 solution, Camfil estimates that the CamGT 3V-600 solution could reduce CO2 emissions by 1000 tonnes per turbine, per year.

The Compact Static EPA system is designed to withstand the harshest environments with space constraints, using the unique high efficiency CamGT 3V-600 filter series. The deeper filter frame offers maximum filter media usage, allowing for unparalleled media area and low media velocity, providing the lowest dP and longest available life on the market.

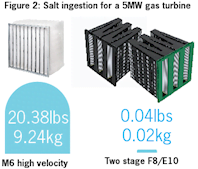

Camfil’s CamGT 3V-600 patented construction featuring vertical pleating and interrupted hot melt separators for optimum water handling allows trapped water to drain freely from the filter during operation, thus avoiding re-entrainment of dissolved impurities and maintaining low and stable dP under high humidity conditions. Figure 2 shows how these features limit salt ingestion , thereby preventing corrosion. This makes the CamGT 3V-600 series the optimal choice for an offshore environment.

Traditional M6 high velocity systems coalesce and remove larger droplets well, but still let through about 20 lbs of salt per year.

A final multistage system lowers salt ingestion to approximately 0.04lbs per year, 99.9% less than a typical high velocity system.