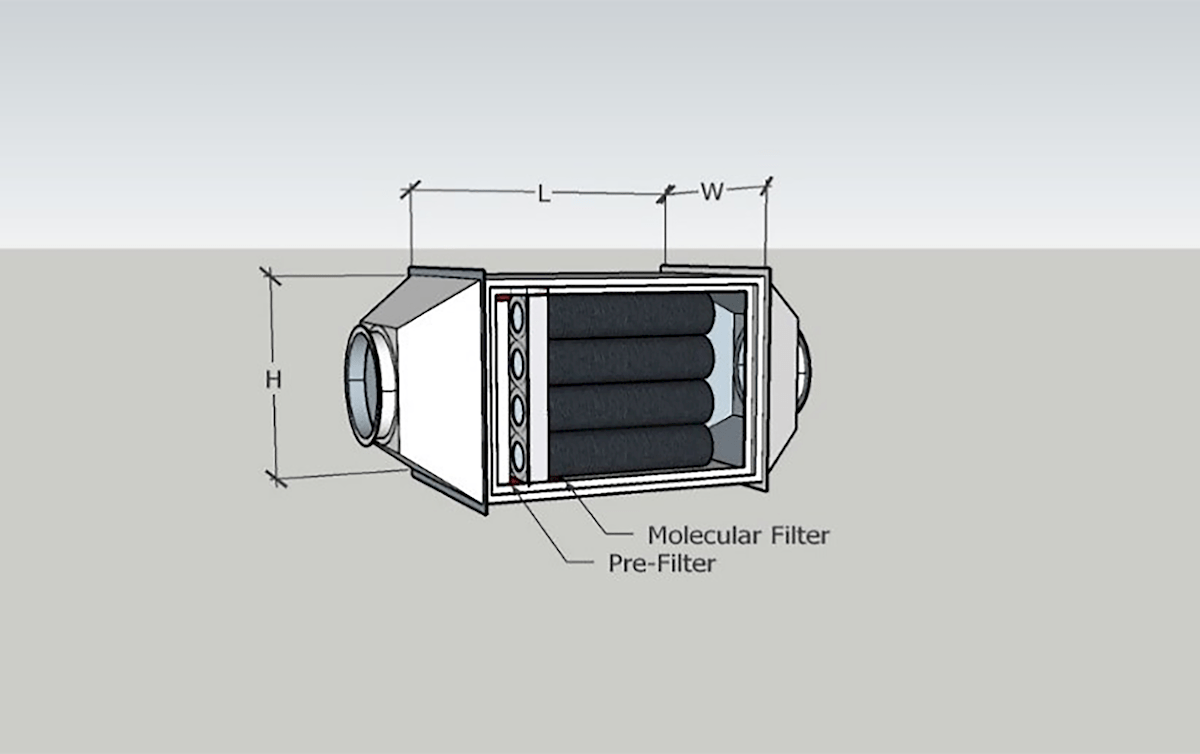

A filtration system was proposed based on the measured VOC concentration and space constraint. The exhaust system comprises a complete filtration solution including 30/30 Panel filters with ISO ePM 10 50% removal efficiency and CamCarb CG 3500 VOC cylinders installed within a customized housing.

The CamCarb CG is a cylindrical, corrosion-resistant molecular filter filled with adsorbents. They are the most versatile gas-phase air filter installed in supply, recirculation, and exhaust air systems in commercial, industrial, and process applications. The design provides a low total cost of ownership for the removal of corrosive, odorous, and irritant gases.

VOC exhaust concentrations were reduced and recorded below the government-mandated maximum limits, thus resolving the customer‘s issue.

3D draft of the solution where exhaust unit is equipped with 30/30 panel pre-filter and CamCarb CG 3500 molecular filter.

A filtration system was proposed based on the measured VOC concentration and space constraint. The exhaust system comprises a complete filtration solution including 30/30 Panel filters with ISO ePM 10 50% removal efficiency and CamCarb CG 3500 VOC cylinders installed within a customized housing.

The CamCarb CG is a cylindrical, corrosion-resistant molecular filter filled with adsorbents. They are the most versatile gas-phase air filter installed in supply, recirculation, and exhaust air systems in commercial, industrial, and process applications. The design provides a low total cost of ownership for the removal of corrosive, odorous, and irritant gases.

VOC exhaust concentrations were reduced and recorded below the government-mandated maximum limits, thus resolving the customer‘s issue.

3D draft of the solution where exhaust unit is equipped with 30/30 panel pre-filter and CamCarb CG 3500 molecular filter.